In recent years, the packaging industry has witnessed significant advancements, with the global market for paste filling machines projected to reach USD 2.5 billion by 2025, growing at a CAGR of 4.8% from 2020. This surge can be attributed to the increasing demand for efficient and precise filling solutions across various sectors, including food and beverage, pharmaceuticals, and cosmetics. As manufacturers strive for improved production efficiency and consistency in product quality, paste filling machines have emerged as a vital component in the packaging process, catering to a variety of viscosity levels and ensuring that products are filled accurately and quickly.

The versatility and technological innovations behind paste filling machines have made them indispensable for global buyers looking to optimize their production lines. Reports indicate that companies implementing advanced filling equipment experience a reduction in filling times by up to 30%, thus enhancing overall operational efficiency. As businesses seek to maintain competitive advantages, understanding the unmatched features of paste filling machines becomes critical. This blog will explore seven key attributes that make these machines essential for manufacturers worldwide, highlighting their role in meeting the evolving demands of the marketplace.

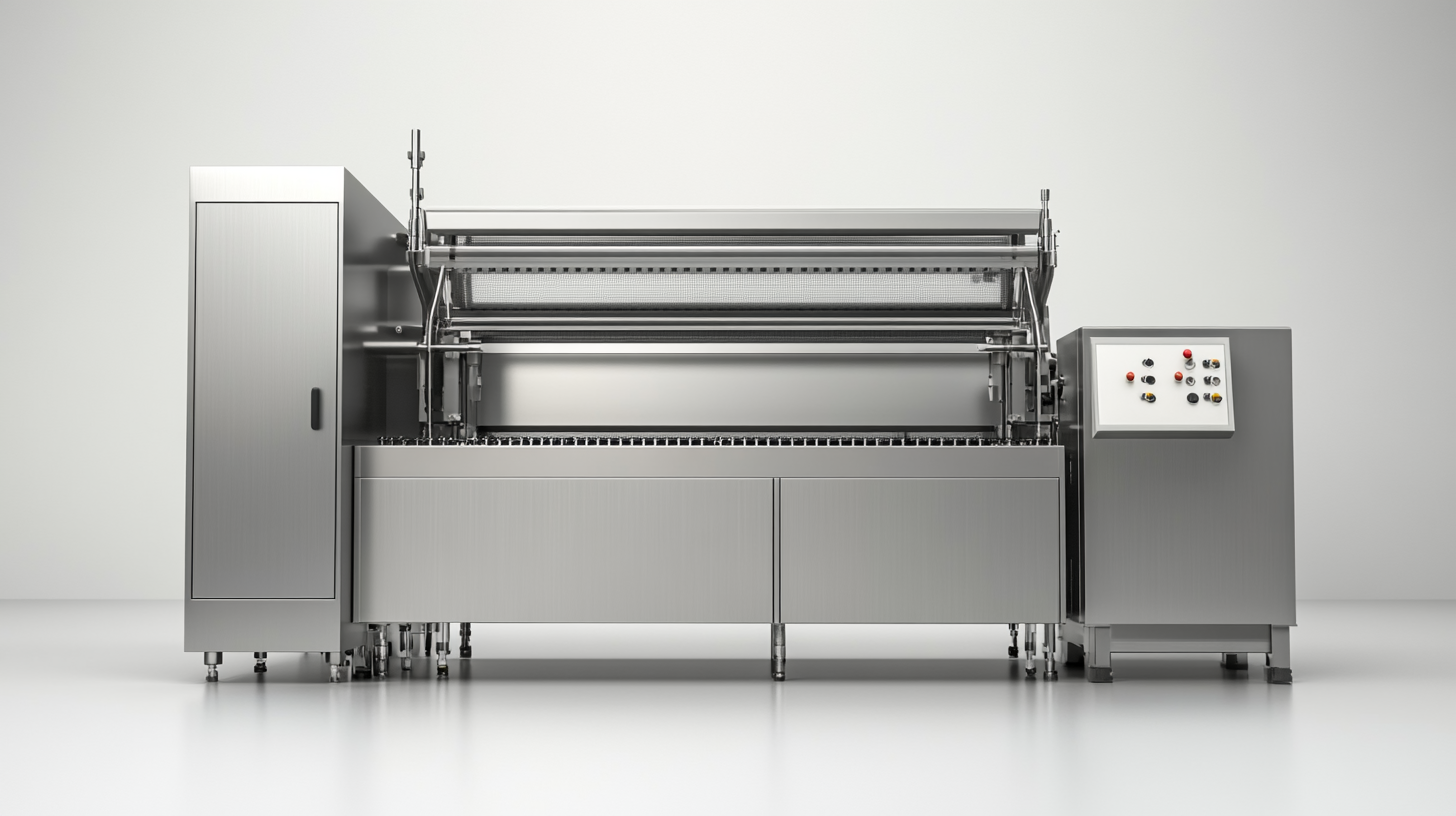

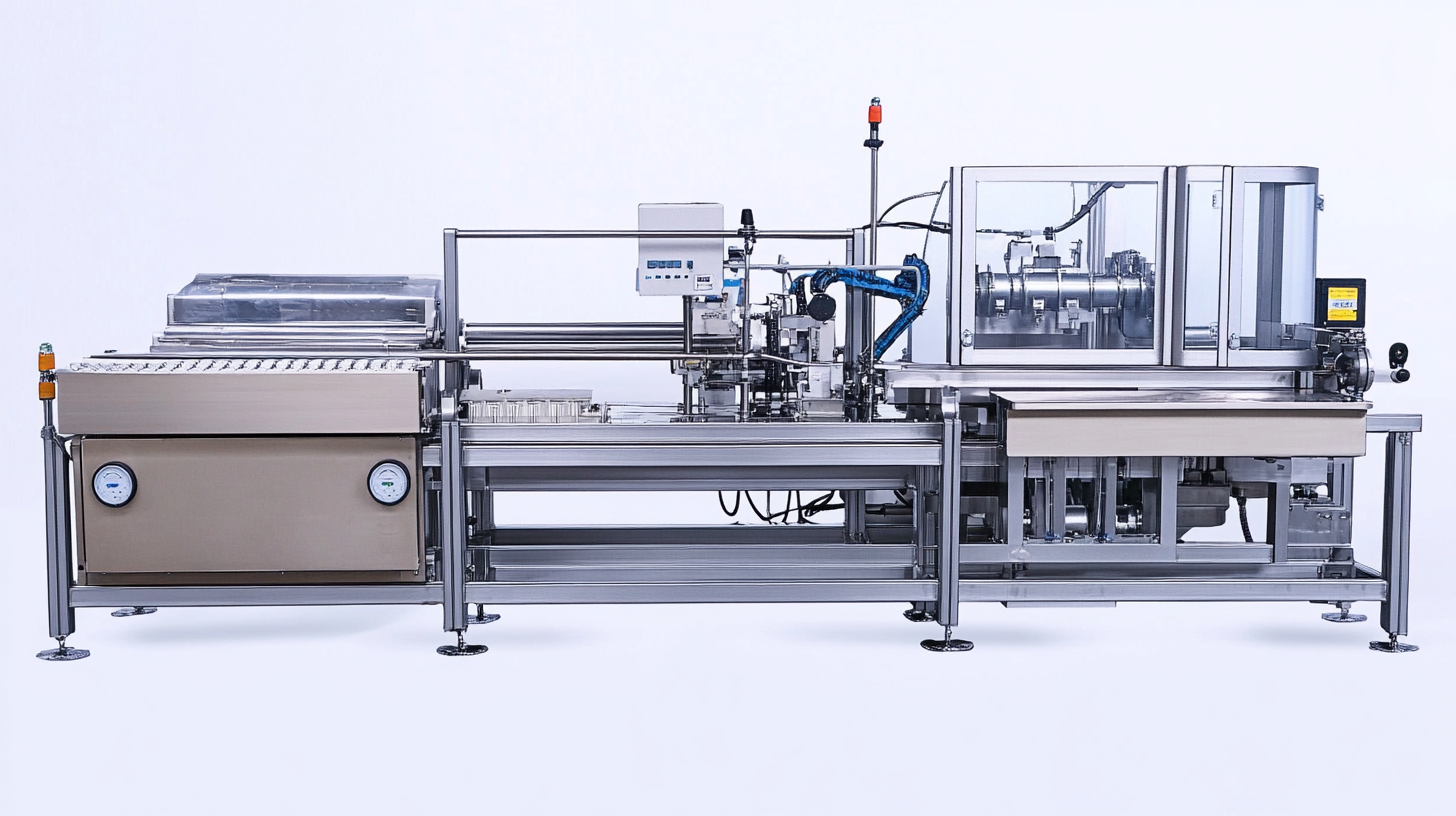

In the ever-evolving landscape of manufacturing, paste filling machines have emerged as a game-changer for companies looking to streamline their production processes. At the heart of these modern machines lies innovative technology that not only enhances efficiency but also improves accuracy in filling a wide range of paste-like products. This technological advancement is pivotal for global buyers seeking reliable solutions to meet their production demands. One of the standout features of contemporary paste filling machines is their integration of smart technology. Many models now utilize advanced sensors and automation systems that can adjust filling parameters in real-time, ensuring consistent product quality with minimal human intervention. This not only reduces the likelihood of errors but also allows for quicker adjustments during different production runs, catering to varied product specifications with ease. Additionally, the implementation of user-friendly interfaces equipped with touchscreen controls has made operation simpler and more intuitive. Operators can easily monitor the entire filling process, adjust settings, and receive immediate feedback on performance metrics. Furthermore, innovative designs also focus on cleanliness and efficiency, incorporating self-cleaning mechanisms and easy disassembly for maintenance, which is increasingly crucial in meeting stringent hygiene standards across the food, cosmetic, and pharmaceutical industries. These advancements not only enhance productivity but also align with the growing demand for sustainable and efficient production practices worldwide.

The versatility of paste filling machines has made them an indispensable asset across a multitude of industries, including food and beverage, pharmaceuticals, cosmetics, and beyond. According to a report by Grand View Research, the global paste filling machine market is expected to reach USD 1.89 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.1%. This growth can be attributed to the machines' ability to handle a variety of viscous fluids, allowing manufacturers to streamline their production lines efficiently.

In the food and beverage industry, these machines are particularly crucial for packaging sauces, jams, and other viscous products. A study by MarketsandMarkets predicts that the food packaging machinery market alone will grow to USD 41.5 billion by 2025, driven by the increasing demand for convenience foods. Paste filling machines can accommodate various bottle sizes and shapes, making them suitable for both small-scale producers and large-scale manufacturers. This adaptability not only enhances production efficiency but also allows brands to cater to diverse consumer preferences.

Similarly, the pharmaceutical sector relies heavily on paste filling machines for the seamless packing of creams, ointments, and dental pastes. According to a report from Mordor Intelligence, the global pharmaceutical packaging market is projected to reach USD 1.3 trillion by 2028, showcasing a significant demand for advanced filling technologies that assure precision and reduce waste. The ability to incorporate state-of-the-art technologies, such as automated filling and capping systems, positions paste filling machines as essential tools for maintaining product integrity and compliance with stringent regulatory standards.

In the realm of manufacturing, paste filling machines have become indispensable, particularly in industries such as food, cosmetics, and pharmaceuticals. Recent advancements in technology have dramatically heightened their efficiency and production speed. According to a report by Technavio, the global paste filling machine market is projected to grow by 7% annually, driven by innovations that improve operational speeds and reduce downtime. This surge reflects the urgent demand for faster processing solutions in today’s competitive environment.

One of the most significant enhancements in these machines is the integration of automation. By employing advanced robotics and control systems, manufacturers have slashed cycle times dramatically. For instance, automated paste filling machines can maintain speeds of up to 120 containers per minute, exceeding manual operations by 300%. Furthermore, the introduction of real-time monitoring and data analytics enables manufacturers to optimize production processes, anticipate maintenance needs, and minimize waste, all of which contribute to an overall increase in efficiency.

Additionally, the versatility of these machines has improved, allowing them to handle a wide range of viscosities and container types without frequent changeovers. The flexibility offered by modern paste filling machines not only streamlines production but also allows for greater customization in product offerings. According to a study by IBISWorld, businesses that have upgraded to these advanced filling systems report a 25% increase in output and a significant reduction in operational costs. As global demands continue to evolve, the enhancements in paste filling technology set a new standard for efficiency and production capabilities in manufacturing.

In the rapidly evolving landscape of manufacturing, paste filling machines have become indispensable for global buyers seeking efficiency and precision. One of the most compelling aspects of these machines is their user-friendly features, which streamline operations and minimize training requirements. According to a recent report by Grand View Research, the global filling equipment market is projected to reach $12.5 billion by 2025, driven largely by advancements in automation and user-centric design.

Modern paste filling machines are equipped with intuitive interfaces that allow operators to make quick adjustments on the fly. This is critical in sectors such as food and beverage, pharmaceuticals, and cosmetics, where precision is paramount. The technology driving these interfaces often includes touchscreens and easy-to-navigate menus, which reduce the learning curve and mitigate the risk of operator error. A study by the International Society of Automation highlights that user-friendly equipment can improve operational efficiency by up to 30%, enabling businesses to scale up their production without a significant increase in labor costs.

Moreover, the ergonomic designs of these machines contribute to safer and more comfortable working environments. Features such as adjustable heights, quick-release mechanisms, and easy-to-clean surfaces have been reported to decrease workplace injuries and improve compliance with safety regulations. The National Safety Council emphasizes that ergonomic improvements in manufacturing can lead to a 20% reduction in workplace injuries, underscoring the importance of user-friendly features not just from a productivity perspective but also from a health and safety standpoint.

As companies continue to embrace automation and digitization, the demand for paste filling machines equipped with user-friendly features is expected to grow. The combination of advanced technology and a focus on operational simplicity positions these machines as a key investment for businesses looking to maintain a competitive edge in a global market.

The safety of both operators and products is paramount in any manufacturing process, particularly in industries that rely on paste filling machines. These advanced machines are designed not only to enhance efficiency and precision but also to incorporate robust safety measures. One of the key features is the inclusion of emergency stop buttons, strategically placed for quick access. This allows operators to halt the machine instantly in case of an emergency, thereby minimizing the risk of accidents.

Moreover, modern paste filling machines are equipped with advanced sensors that monitor the filling processes closely. These sensors can detect abnormalities, such as fluctuations in pressure or inconsistencies in the paste flow. When such issues arise, the machine can automatically shut down or alert operators, preventing potential hazards. Additionally, many machines come with safety guards and shields, which protect operators from any moving parts or splashes of product during the filling process, further enhancing workplace safety.

In terms of product protection, paste filling machines are designed to maintain hygiene and prevent contamination. Features such as easy-to-clean materials and enclosed filling systems ensure that products remain safe and compliant with food safety standards. This is crucial not only for the safety of the end product but also for maintaining the integrity of the brand. Ultimately, investing in paste filling machines with robust safety measures not only protects operators but also upholds the quality and safety of the products being manufactured.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm