In the fast-paced world of manufacturing, efficiency and precision are paramount, particularly in the packaging sector. A key component that plays a crucial role in ensuring both is the Filling Machine. According to a report by MarketsandMarkets, the global filling machine market is expected to grow from USD 4.5 billion in 2021 to USD 6.5 billion by 2026, at a compound annual growth rate (CAGR) of 7.9%. This growth underscores the increasing demand for high-quality filling solutions that can enhance productivity while maintaining product integrity.

Utilizing advanced filling machines can significantly streamline production lines across various industries, including food and beverage, pharmaceuticals, and cosmetics. The advantages of investing in high-quality equipment extend beyond mere speed; they encompass accuracy, versatility, and the ability to adapt to ever-changing market demands. As highlighted in a report by Mordor Intelligence, companies that implement state-of-the-art filling machines often witness a reduction in waste and a boost in overall operational efficiency, further emphasizing the importance of selecting the right filling technology for your production landscape.

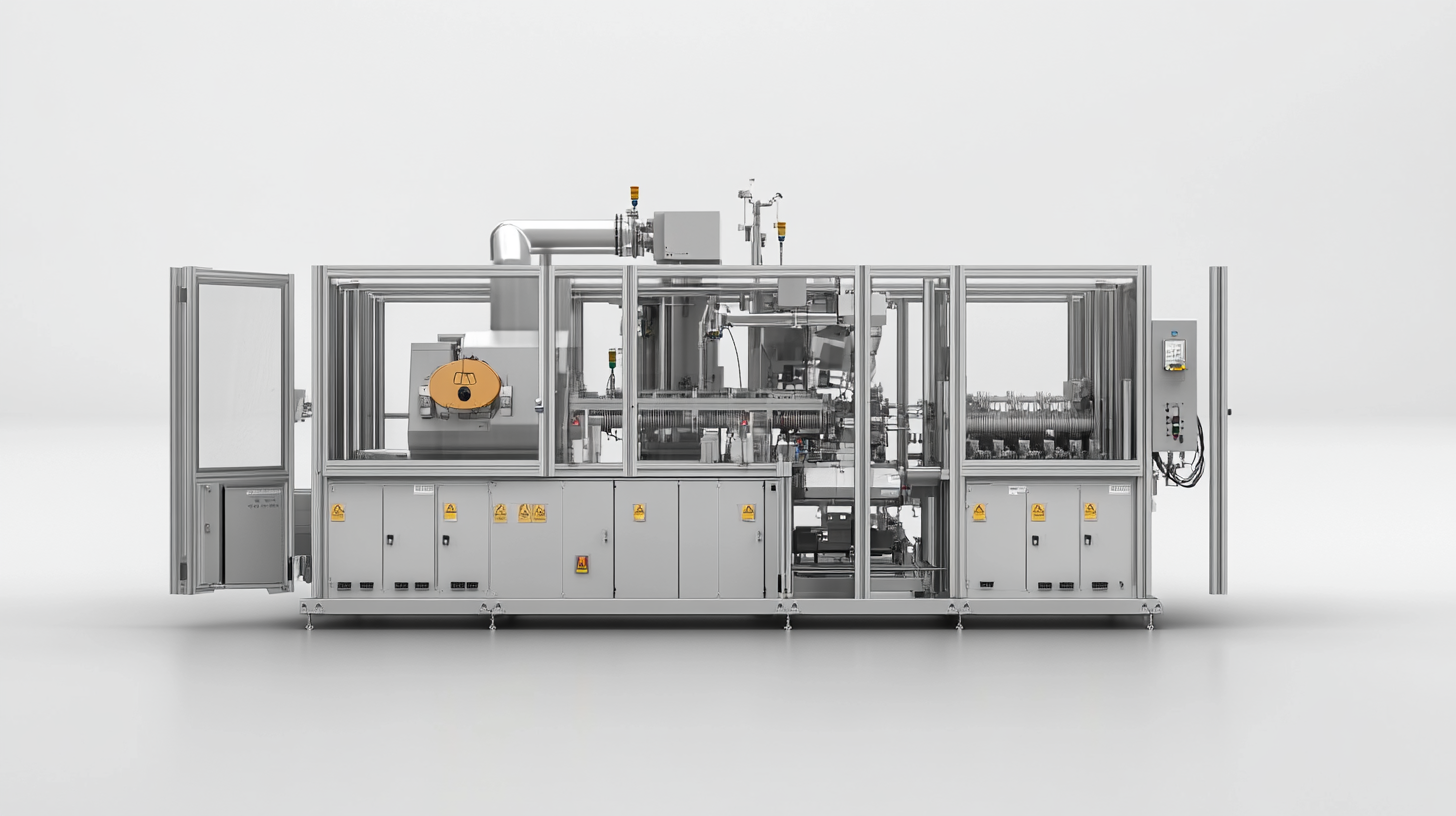

High-quality filling machines are pivotal in the manufacturing landscape, particularly in industries where precision and efficiency are paramount. These machines ensure that products are filled accurately and consistently, reducing the risk of wastage and rework. This reliability not only enhances product quality but also streamlines the production workflow, allowing manufacturers to meet market demands effectively. Moreover, the importance of investing in high-quality filling machines extends beyond mere accuracy in filling. These machines are designed with advanced technology that enables swift adjustments for different product types, sizes, and formats. This adaptability reduces downtime during production runs and enhances the overall productivity of the manufacturing line. As industries evolve and consumer preferences shift, the ability to pivot quickly without compromising on quality becomes a critical factor for success. In addition to operational efficiency, high-quality filling machines contribute to safety standards within the production environment. Machines built with superior materials and advanced safety features minimize the risk of accidents and contamination, protecting both the product and the workers. This aspect is especially crucial in sectors like food and beverage, pharmaceuticals, and cosmetics, where regulatory compliance and consumer safety are vital. Thus, understanding the significance of high-quality filling machines is essential for businesses looking to optimize their manufacturing processes while maintaining product integrity and safety.

In today's competitive production landscape, investing in high-quality filling machines is essential for efficiency and accuracy in the manufacturing process. When selecting the right machine for your production line, it is important to consider key features that directly impact performance. These features include speed, precision, and adaptability to different container types, such as vials, syringes, and tubes, which are becoming increasingly prevalent in various industries, including pharmaceuticals and food and beverage.

Speed is a crucial factor as it dictates how quickly products can be filled and packaged, ultimately affecting overall productivity. Additionally, precision in filling ensures that the correct amount of product is dispensed, reducing waste and improving customer satisfaction. Furthermore, with the rise of robotic technology, machines capable of washing and filling vials are gaining traction, driven by the growing demand for injectable drugs in health care sectors. This adaptability supports different production needs, ranging from small-scale operations to larger manufacturing setups, allowing businesses to remain flexible in their operations.

Investing in filling machines equipped with the latest technology not only streamlines production lines but also positions companies to meet the increasing demand for packaged goods. Features such as easy integration into existing systems, low maintenance requirements, and high-energy efficiency are additional benefits that enhance the long-term viability of equipment. Ultimately, choosing high-quality filling machines tailored to your production line can unlock significant advantages, ensuring that your operations run smoothly and efficiently.

High-quality filling machines play a crucial role in enhancing production efficiency for industries across the globe. As the liquid filling machinery market is projected to grow from $6.82 billion in 2025 to $10.39 billion by 2032, expanding at an annual growth rate of 6.2%, it’s clear that manufacturers are recognizing the importance of investing in advanced technologies. These machines not only streamline the filling process but also ensure precision and consistency, which are vital for maintaining product quality and minimizing waste.

The integration of artificial intelligence, robotics, and automation in traditional manufacturing sectors is driving a significant transformation in efficiency. High-quality filling machines equipped with intelligent features can adapt to production line changes in real-time, resulting in optimized operations and reduced downtime. This technological shift facilitates faster production cycles, allowing manufacturers to meet increasing consumer demand without compromising on quality.

Moreover, the rise of smart filling solutions is pushing manufacturers to reevaluate their processes. Continuous advancements in machine design and functionality mean that the latest filling machines can handle a variety of substances—ranging from water to viscous liquids—making them versatile assets in diverse production environments. Embracing these high-quality machines is not just an investment in equipment; it’s a strategic decision that enhances overall production capacity and efficiency.

Investing in advanced filling technology can yield significant cost benefits for production lines. High-quality filling machines are designed to enhance efficiency and reduce waste, which directly translates to cost savings. These machines often possess higher accuracy in filling volumes, minimizing product loss due to overfills or spills. This precision not only preserves the integrity of the product but also maximizes the profitability of each batch produced. Manufacturers can save on raw materials while ensuring that consumer expectations for quantity and quality are consistently met.

Moreover, modern filling technology often comes equipped with automation features that streamline the production process. By reducing manual labor and associated operational costs, businesses can allocate resources more effectively. Automated filling systems can operate at faster speeds while maintaining accuracy, resulting in increased throughput. This efficiency is particularly advantageous in high-demand environments where meeting production targets is crucial for staying competitive. Additionally, advanced machines require less maintenance, further saving costs on repair and downtime.

In the long run, the initial investment in high-quality filling machines pays off through decreased operational costs and increased efficiency. Companies that embrace these technologies position themselves to adapt to market demands swiftly while enjoying sustained profitability. The transition to modern filling solutions not only boosts immediate financial benefits but also fortifies a company's competitive edge, ensuring long-term success in a challenging economic landscape.

Filling machines play a crucial role in various industries, ensuring efficiency and precision in the packaging process. In the food and beverage sector, for example, these machines are essential for accurately dispensing liquids like sauces, oils, and beverages into bottles and jars. The use of high-quality filling machines not only speeds up production but also minimizes waste, providing manufacturers with significant cost savings. Additionally, in this industry, maintaining hygiene and adhering to safety standards is paramount, and modern filling machines come equipped with features that help meet these stringent requirements.

In the pharmaceutical and cosmetics industries, filling machines are designed to handle a variety of products, including creams, lotions, and liquid medications. These machines are often equipped with advanced technology to ensure the sterile handling of sensitive substances, which is critical for maintaining product integrity and safety. Automated filling systems in these sectors enhance production rates while reducing the risk of human error, thus ensuring a consistent level of quality across all packaged products.

Moreover, in the chemical industry, filling machines must work with a range of materials, from viscous substances to powdered products. Advanced filling technology not only accommodates these diverse materials but also allows for customization based on specific production needs. The versatility of high-quality filling machines enables manufacturers to adapt to market demands swiftly, ultimately driving innovation and efficiency within their production lines.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm