In today's fast-paced business environment, efficiency and precision are paramount for success, particularly in the packaging industry. The advent of technology has significantly transformed how products are packaged, and one standout innovation is the Sachet Filling Machine. This remarkable piece of equipment streamlines the process of filling and sealing sachets, catering to various industries from food and beverages to pharmaceuticals. By automating this crucial task, businesses can not only enhance productivity but also ensure consistent quality and reduce operational costs. In this blog, we will explore seven amazing benefits of using a Sachet Filling Machine for your business, showcasing how this investment can optimize your operations, improve product presentation, and ultimately drive growth in a competitive market. Whether you're a small enterprise or a large manufacturer, understanding the advantages of incorporating a Sachet Filling Machine into your workflow can set you on the path to success.

Sachet filling machines have become integral in the packaging industry, providing numerous advantages to businesses. As the global market for stickpack, stick bag, and sachet packaging machines is projected to reach $5.8 billion by 2033, understanding the importance of these machines is paramount. The increasing demand for efficient, cost-effective, and versatile packaging solutions is driving this robust growth, making sachet filling machines an essential investment for businesses looking to enhance their operational efficiency and product presentation.

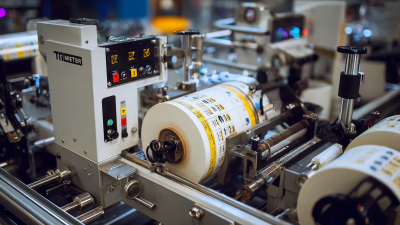

One of the key benefits of using sachet filling machines is their ability to maintain seal integrity in heat-sealed flexible food packages. Recent studies have shed light on the mechanisms behind heat sealing, emphasizing the critical factors that influence the durability of these seals. Effective sealing methods not only ensure product safety and longevity but also improve overall packaging aesthetics, which is vital in attracting consumers. Additionally, manufacturers are innovating in pouch filling technologies to enhance machinery efficiency and product reliability, enabling businesses to meet the diverse needs of their customers and remain competitive in the market.

Sachet filling machines are revolutionizing the packaging industry by significantly enhancing production efficiency. By automating the filling process, these machines reduce the time and labor required for packaging operations. This automation not only speeds up throughput but also minimizes the risk of human error, ensuring that each sachet is filled accurately and consistently. Businesses can focus on scaling their production without the worry of potential bottlenecks caused by manual filling processes.

Moreover, these machines offer versatility in packaging a wide range of products, from food items to pharmaceuticals. With adjustable settings, companies can easily switch between different sachet sizes and materials, enhancing their ability to adapt to market demands. This flexibility is crucial in a fast-paced business environment where customer preferences can shift rapidly. By optimizing production workflows through the use of sachet filling machines, businesses can maintain a competitive edge, ensuring timely delivery and high-quality products that meet consumer expectations.

| Benefit | Description | Impact on Business |

|---|---|---|

| Increased Production Speed | Sachet filling machines can significantly speed up the packaging process. | Leads to higher output and meets market demand promptly. |

| Consistency in Filling | They ensure uniform filling volumes, reducing errors and waste. | Increases product quality and customer satisfaction. |

| Reduced Labor Costs | Automation reduces the need for manual labor in packaging. | Saves money on labor and reallocates workforce to other areas. |

| Versatility | Can fill a variety of products, from powders to liquids. | Allows businesses to expand product lines and offerings. |

| Space Efficiency | Compact designs save valuable floor space in production areas. | Optimize facility layout, enhancing overall productivity. |

| Improved Shelf Life | Proper sealing techniques extend the product's shelf life. | Reduces waste from spoilage and enhances customer trust. |

| Cost-effective | Lower packaging costs per unit when using sachet machines. | Improves margins and profitability. |

Investing in a sachet filling machine can lead to significant cost savings for businesses of all sizes. One of the primary financial advantages is the reduction in labor costs. Automating the packaging process allows companies to reallocate human resources to more critical areas of operation. This not only streamlines production but also minimizes the risk of errors associated with manual labor, which can lead to costly rework and waste.

Additionally, sachet machines can enhance efficiency, allowing for higher output in a shorter amount of time. This increased productivity translates directly into better profit margins. By optimizing the filling process, businesses can reduce material waste and ensure that every sachet is filled accurately, maximizing the use of materials. The initial investment in sachet technology may seem substantial, but the long-term savings and increased profitability make it a worthy consideration for any forward-thinking business aiming to enhance its operational effectiveness.

Improved product freshness is a critical concern for businesses, particularly in sectors such as food, pharmaceuticals, and cosmetics. Utilizing a sachet filling machine can significantly enhance how products are packaged, ensuring that freshness is maintained right up until they reach the consumer. These machines are designed to create tight seals that prevent air and moisture from compromising the quality of the contents inside. This is especially important for products that are prone to spoilage or degradation when exposed to environmental factors.

Furthermore, the precision and efficiency of sachet filling machines allow for consistent fills and precise volumes, which translates to minimal waste and optimal usage of materials. By ensuring that each sachet is properly filled and sealed, businesses can maintain not just the freshness but also the integrity and efficacy of their products. This level of quality control not only leads to improved customer satisfaction but can also enhance brand reputation, as consumers increasingly seek products that guarantee freshness and reliability. Investing in a sachet filling machine can therefore be a pivotal step for businesses that prioritize quality packaging and wish to stand out in a competitive marketplace.

Sachet filling machines are increasingly recognized for their adaptability in various industries, offering both versatility and customization. According to a report by Grand View Research, the global sachet packaging market is projected to reach USD 30.53 billion by 2025, indicating a growing demand for efficient packaging solutions. This trend reflects how businesses can tailor sachet machines to meet their specific needs, from packaging food products to pharmaceuticals. Customization options allow for adjustments in size, material, and sealing techniques, enabling companies to enhance their brand identity while maintaining efficiency.

Moreover, the flexibility of sachet machines extends to their capability to handle diverse products. A study from MarketsandMarkets highlights that the food and beverage sector alone is expected to contribute significantly to the sachet packaging market, driven by consumer preferences for single-serve and convenient packaging. By adapting sachet machines to different product types—liquid, powder, or granular—businesses can respond to market trends and consumer demands swiftly. This not only improves operational efficiency but also ensures that companies remain competitive in an evolving marketplace, reinforcing the critical role of versatile and customizable solutions in the success of modern businesses.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm