In today's competitive market, selecting the right Lotion Filling Machine has become increasingly important for manufacturers looking to enhance efficiency and maintain product quality. According to a recent industry report by Smithers Pira, the global personal care packaging market is projected to reach $50 billion by 2025, highlighting the growing demand for effective filling solutions in the sector. As businesses prioritize scalability and automation, understanding the nuances of various lotion filling machines is essential.

This ultimate checklist will guide manufacturers through critical factors to consider, including machine performance, ease of cleaning, and compatibility with diverse lotion formulations. By making informed choices, companies can not only streamline their production processes but also cater to evolving consumer preferences, ultimately driving profitability and market growth.

When selecting a lotion filling machine for your business, it is crucial to consider several key factors that can significantly impact your production efficiency and product quality. First, assess the machine’s compatibility with your lotion's viscosity and specific formulation. Different formulations may require distinct filling techniques, such as gravity filling for thinner lotions or vacuum filling for thicker consistencies. Understanding the nature of your product will guide you toward a machine designed for optimal performance with your specific formulation.

Additionally, investigate the technological features of the lotion filling machine. Options that include programmable settings can enhance flexibility, allowing you to efficiently adjust filling volumes and speeds as your product lineup evolves. Given the growing market demand for various lotions and personal care products, the ability to adapt your production line to accommodate new products is essential. Furthermore, consider the machine’s throughput and reliability, as these factors directly influence your operational capacity and overall profitability in a competitive market where efficiency is key.

| Factor | Description | Importance Level | Price Range |

|---|---|---|---|

| Filling Accuracy | The precision of the machine in filling lotion to the desired volume without wastage. | High | $10,000 - $30,000 |

| Production Speed | The number of bottles the machine can fill in a given time frame. | Medium | $5,000 - $20,000 |

| Ease of Use | How user-friendly the machine is for operators, including ease of setup and operation. | High | $3,000 - $15,000 |

| Size and Footprint | The physical dimensions of the machine and the space it requires in your facility. | Medium | $4,000 - $12,000 |

| Maintenance Needs | How often the machine requires maintenance and the associated costs. | High | $2,000 - $10,000/year |

| Compatibility with Different Bottle Types | Whether the machine can handle various sizes and types of lotion bottles. | Medium | $3,000 - $8,000 |

| Warranty and Support | The terms of the warranty and the availability of technical support. | High | Varies |

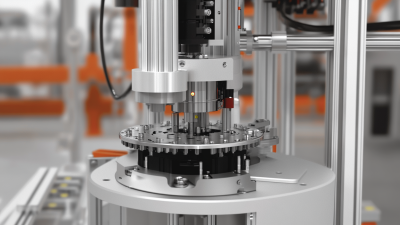

When it comes to choosing the right lotion filling machine, understanding the different types available is crucial for ensuring that your production process runs smoothly. There are several key types of lotion filling machines to consider, each designed to meet specific needs. For instance, gravity filling machines are ideal for thinner lotions, as they allow for a free-flowing process that accurately dispenses product without introducing air or bubbles. On the other hand, piston filling machines are perfect for thicker lotions and creams, utilizing a piston-driven mechanism that can handle viscous products with precision.

Additionally, if you require versatility in your production line, look into vacuum filling machines. These are particularly effective for products that are sensitive to air exposure, as the vacuum process minimizes oxidation. Another option is the overflow filling machine, which ensures consistent filling levels by using a controlled overflow method. By carefully evaluating the characteristics of your lotion and the requirements of your packaging process, you can select the machine that best aligns with your operational needs, enhancing both efficiency and product quality.

When selecting a lotion filling machine, it is crucial to prioritize industry standards and compliance to ensure safety and efficiency. Manufacturers must adhere to regulations set forth by organizations like the FDA and ISO. These standards help guarantee that the machinery operates safely and produces high-quality products. Before finalizing your choice, examine the certifications of the machine, as well as the manufacturer's compliance history. This step can save you from potential legal troubles and enhance your brand’s reputation.

Tip: Always request validation documents from the manufacturer to verify that their lotion filling machine meets applicable safety regulations. Additionally, it’s essential to assess whether the equipment can be easily cleaned and maintained. Hygiene is paramount in the cosmetics industry, and machines that allow for quick disassembly and thorough cleaning will enable compliance with safety regulations.

Another important consideration is the machine's capacity and versatility. Ensure the lotion filling machine can accommodate different product viscosities and packaging sizes, as this flexibility is key to meeting diverse customer needs. Investing in equipment with adjustable settings will facilitate compliance with various safety standards while helping your production keep pace with market demands.

When evaluating lotion filling machinery, the balance between cost-effectiveness and quality is paramount for ensuring a good return on investment (ROI). Businesses often face the dilemma of choosing between low-cost machines that may compromise on durability and efficiency or higher-priced, premium options that promise longevity and superior performance. A thorough assessment of operational needs and production volume can help in aligning the choice of machinery with budgetary constraints while maximizing output.

Investing in a quality lotion filling machine often translates into lower maintenance costs and enhanced productivity over time. Consider the long-term savings that come from fewer breakdowns and less downtime, which can significantly impact overall profitability. Additionally, features such as automation and precision filling not only improve speed but also reduce material waste—further enhancing ROI. Therefore, discerning the long-term benefits of quality against the immediate allure of cost savings is crucial for businesses aiming to thrive in the competitive skincare industry.

Maintaining your lotion filling equipment is crucial for ensuring its longevity and optimal performance. Regular cleaning should be a priority; build-up from lotions and creams can result in clogs and inefficiencies. After each use, it’s advisable to disassemble and clean all parts that come into contact with the product. Use warm, soapy water and a soft cloth to remove any residue, and avoid abrasive materials that could scratch the surfaces. Additionally, implementing a scheduled maintenance program can help catch potential issues before they become expensive repairs.

Another important aspect of maintenance is monitoring the machine's settings and calibration. Misalignment or incorrect settings can not only affect the filling accuracy but can also lead to premature wear and tear on the equipment. Regularly checking the filling volume and adjusting it as necessary helps in maintaining consistency, which is essential for product quality. Furthermore, keeping an eye on the seals, valves, and tubing for signs of wear will ensure that your lotion filling machine operates smoothly and effectively for years to come.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm