In today's highly competitive market, the efficiency and precision of labeling can significantly impact a business's success. The Label Applicator Machine has emerged as a critical tool for manufacturers aiming to meet industry standards while enhancing productivity. According to a report by MarketsandMarkets, the global label applicators market is projected to grow from USD 3.8 billion in 2020 to USD 5.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.4%. This growth underscores the increasing reliance on automated labeling solutions in various sectors, such as food and beverage, pharmaceuticals, and cosmetics. As companies strive for operational excellence and compliance with international standards, investing in the best label applicator machine not only facilitates compliance but also enhances brand integrity and consumer trust. By understanding the advantages of advanced labeling technology, businesses can position themselves to win global respect through quality, exemplifying China's manufacturing prowess in delivering reliable and efficient solutions.

In the fast-evolving landscape of manufacturing, adhering to industry standards is paramount for selecting the best label applicator machines. These standards not only ensure quality and safety but also enhance operational efficiency. For instance, the Supply of Machinery (Safety) Regulations 2008 in Great Britain outlines specific requirements that must be fulfilled before machinery can be introduced into the market. Such regulations serve as a benchmark, ensuring that label applicators not only meet safety requirements but also contribute to the overall efficiency of production lines.

Moreover, the role of industry standards can be likened to frameworks found in other sectors, such as machine learning. Just as clarity in machine learning standards can drive fairness and transparency, standardized practices in labeling machinery can lead to improved consistency and reliability in product packaging. As highlighted in a recent discussion on regulation vs. standards in machine learning, creating common technical standards can streamline processes and mitigate risks. This is particularly crucial for businesses looking to maintain a competitive edge while ensuring compliance with regulatory frameworks in their operations. Implementing industry standards in label applicators could very well be the key to achieving operational excellence and compliance in today’s market.

Moreover, the role of industry standards can be likened to frameworks found in other sectors, such as machine learning. Just as clarity in machine learning standards can drive fairness and transparency, standardized practices in labeling machinery can lead to improved consistency and reliability in product packaging. As highlighted in a recent discussion on regulation vs. standards in machine learning, creating common technical standards can streamline processes and mitigate risks. This is particularly crucial for businesses looking to maintain a competitive edge while ensuring compliance with regulatory frameworks in their operations. Implementing industry standards in label applicators could very well be the key to achieving operational excellence and compliance in today’s market.

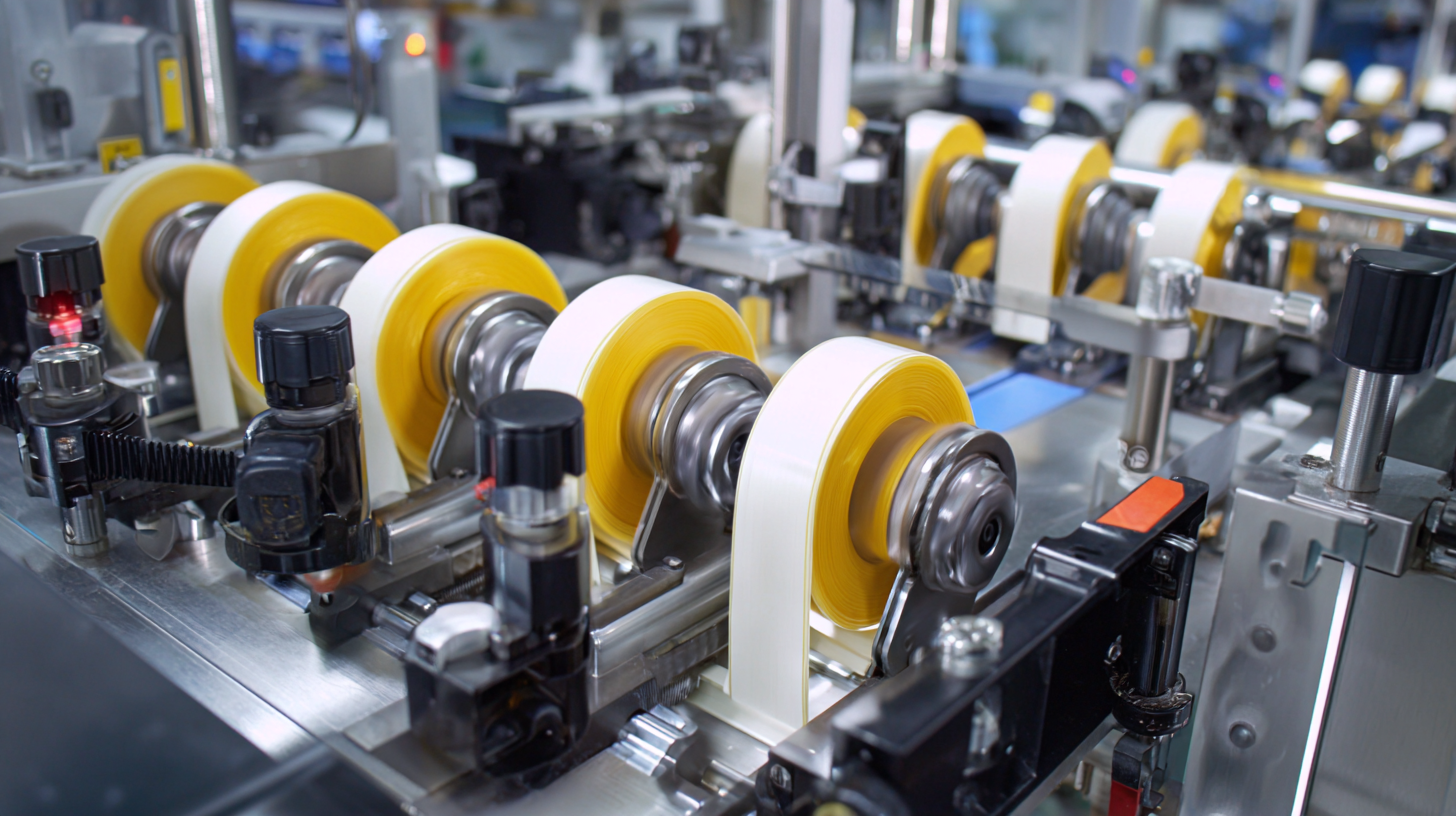

When selecting a high-quality label applicator machine for your business, certain key features are essential to ensure efficiency and effectiveness in your labeling process. First and foremost, look for a model that offers precision application. Consistent label placement not only enhances the aesthetic appeal of your products but also reduces waste caused by misaligned labels. A machine with adjustable settings allows you to accommodate various label sizes and shapes, making it versatile for diverse packaging needs.

Another important feature is the speed of operation. A label applicator that can quickly and accurately apply labels boosts your productivity and helps meet high-volume demands. Consider machines with automation capabilities, as these can significantly reduce manual labor and streamline your workflow.

Tip: Always assess the ease of maintenance. A user-friendly design that allows for quick cleaning and part replacements can save valuable time and minimize production downtime. Investing in an applicator with a solid warranty and customer support can also protect your investment and ensure smooth operations in the long run.

| Feature | Importance | Benefits | Considerations |

|---|---|---|---|

| Speed | High efficiency in production | Increases throughput, reduces labor costs | Assess based on production volumes |

| Accuracy | Minimize mislabeling | Ensures product compliance, enhances brand reputation | Evaluate features that enhance precision |

| Versatility | Ability to handle various label types | Adapts to different packaging needs | Ensure compatibility with your products |

| Ease of Use | User-friendly interface | Reduces training time and increases operational efficiency | Consider staff adaptability |

| Durability | Long-term investment | Lower maintenance costs, longer lifespan | Check warranty and service options |

| Integration | Compatibility with existing systems | Streamlines workflow and data management | Ensure software compatibility |

The landscape of the label applicator market is increasingly influenced by China's manufacturing prowess. As the country continues to solidify its position as a global manufacturing superpower, accounting for 29% of worldwide manufacturing output in 2023, its impact on industries such as labeling cannot be overstated. The rapid advancements in technology and innovation capabilities within Chinese companies make them formidable competitors on the global stage. As businesses look to upgrade their operations, understanding why Chinese manufacturers dominate this market becomes crucial.

When selecting the best label applicator for your business, investing in quality is key. Research suggests that the global flexographic printing machine market is anticipated to grow at a CAGR of 6.0% from 2024 to 2030, emphasizing the rising demand for precision and efficiency in labeling technologies. Businesses should prioritize machines that offer advanced features and reliability to stay competitive.

Tips: Always assess a machine’s specifications against your production needs. Additionally, consider the machine's adaptability to different labeling processes to ensure it meets evolving market trends. Lastly, explore suppliers with strong after-sales support to minimize downtime and maintain productivity.

Investing in the best label applicator machine is crucial for businesses aiming for long-term success, particularly in today’s competitive market. A high-quality applicator not only improves efficiency and accuracy in labeling processes but also significantly reduces operational costs over time. The initial investment might seem substantial, but the returns come in the form of minimized waste, reduced labor costs, and enhanced productivity. As generative AI continues to revolutionize various industries, businesses must adapt and leverage technology to optimize all facets of production, including packaging and labeling.

Moreover, as companies increasingly focus on environmental, social, and governance (ESG) criteria, choosing label applicators that align with sustainable practices has become imperative. The right machinery can contribute to a greener operation, adhering to emerging regulations and consumer preferences for environmentally friendly practices. Ultimately, selecting a top-notch label applicator not only positions a business for immediate operational success but also aligns with long-term objectives of sustainability and cost-effectiveness in a rapidly evolving industrial landscape.

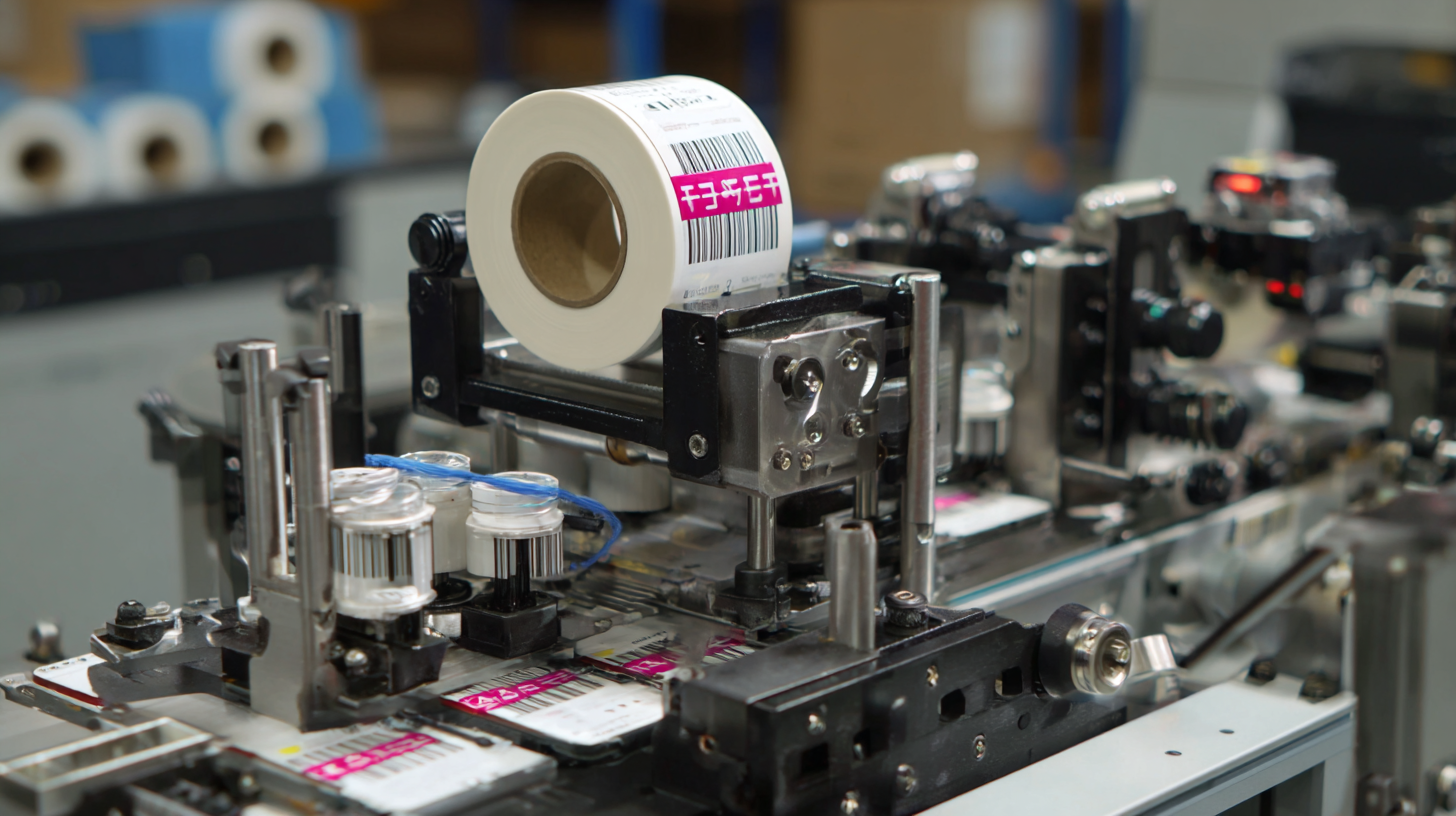

In today's fast-paced industrial landscape, the integration of advanced labeling solutions has become paramount across various sectors. For instance, a recent report by the Label and Narrow Web Industry indicated that automated labeling systems can enhance operational efficiency by up to 30%, significantly reducing labor costs and minimizing errors in the production line. Industries ranging from food and beverage to pharmaceuticals are reaping the rewards of these sophisticated machines, which provide precision and consistency in labeling.

One of the key benefits of advanced label applicators is their ability to meet stringent regulatory requirements, especially in sectors like healthcare, where compliance is non-negotiable. According to a study from the FDA, accuracy in labeling can directly impact consumer safety, making reliable labeling systems essential. Additionally, businesses can leverage Variable Data Printing (VDP) technology to personalize labels in real time, improving customer engagement and satisfaction.

Tip: When selecting a label applicator machine, consider your production volume and the type of labels you use. Investing in a machine that can handle diverse label formats can enhance flexibility and reduce downtime. Moreover, ensure that the machine's software is compatible with your existing systems for seamless integration.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm