In today's fast-paced production environment, selecting the right Bottle Capping Machine is crucial for ensuring efficiency and maintaining product integrity. According to industry reports, the global bottle capping machine market is projected to reach USD 6 billion by 2026, growing at a CAGR of 5% from 2021 to 2026. This growth is driven by the increasing demand for packaged beverages and food products, which has made reliable capping technologies essential for manufacturers aiming to optimize their operations. The right capping machine not only enhances productivity but also guarantees that products are securely sealed, thereby reducing spoilage and extending shelf life. As such, understanding the various types and functionalities of bottle capping machines available is vital for businesses keen to meet their production needs effectively.

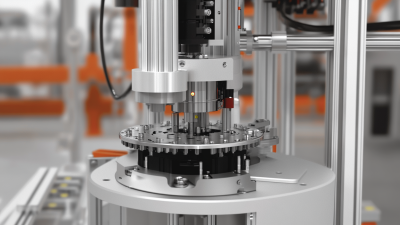

When it comes to selecting the right bottle capping machine for your production needs, it’s essential to understand the different types available and their unique features. The most common types include automatic, semi-automatic, and manual capping machines. Automatic machines are best suited for high-volume production lines, as they can significantly increase efficiency and consistency by automatically feeding, capping, and rejecting bottles. They often come with advanced technology, such as sensors and monitoring systems, ensuring precise cap placement and reduced downtime.

On the other hand, semi-automatic capping machines offer flexibility and are ideal for medium-sized operations. These machines still enhance productivity while allowing operators to have more control over the capping process. Manual capping machines, while requiring more human intervention, are cost-effective solutions for small-scale producers or businesses just starting out. Each type features various capabilities, such as different cap types—screw caps, snap-on caps, or corks—making it crucial to consider your specific product needs when making a choice.

When considering bottle capping machines, the choice between automatic and manual options greatly influences production efficiency. Automatic bottle capping machines, known for their speed and precision, can cap up to 1,200 bottles per hour, significantly reducing labor costs and minimizing human error. In contrast, manual capping machines may only cap around 200 to 300 bottles per hour, making them more suitable for smaller operations or startups that do not yet require high-volume output.

Moreover, automatic systems often come equipped with advanced features such as cap sorting and rejection mechanisms, which enhance product quality and reduce waste. According to a 2023 industry report, manufacturers opting for automated machines have reported a 30% increase in overall productivity compared to those using manual methods. Additionally, these automatic machines can handle a variety of bottle types and sizes, making them a versatile choice for growing businesses looking to scale their operations. Thus, understanding the benefits of each system is crucial for making an informed decision that aligns with specific production needs.

When selecting a bottle capping machine, understanding how production volume influences your equipment choice is critical.

According to a recent report by Grand View Research, the global bottling equipment market is projected to reach $21.2 billion by 2025, highlighting the growing demand for efficient capping solutions. For productions around 1,000 bottles per hour, semi-automated capping machines are often adequate, providing flexibility and cost-effectiveness. These machines can handle varying bottle sizes and cap types, making them ideal for small to medium-sized enterprises that experience fluctuating production volumes.

Conversely, for manufacturers with higher output requirements, such as those producing more than 5,000 bottles per hour, a fully automated capping system becomes essential. A study by MarketsandMarkets suggests that automation in bottling processes can improve production efficiency by up to 30%, which is crucial for keeping up with the increasing demand in industries like beverage and pharmaceuticals. Moreover, automated capping machines reduce the risk of human error, ensuring consistency and reliability in sealing, which is vital for maintaining product integrity and compliance with industry standards. As your production volume scales, so should your capping machinery to meet the evolving demands of your business.

When investing in a bottle capping machine, it’s essential to consider not just the initial purchase price but also the long-term savings it can offer. A high-quality machine may come with a higher upfront cost, but its durability and efficiency can significantly reduce maintenance and operational expenses over time. For instance, machines that are built with robust materials often require fewer repairs, thereby lowering overall downtime and keeping production on track.

**Tip:** Always request a total cost of ownership analysis from suppliers. This analysis should include operating costs, potential repair expenses, and expected lifespan to help you make an informed decision.

Additionally, energy efficiency is a crucial factor that can contribute to cost savings. A machine that utilizes less energy not only lowers utility bills but can also enhance your company's sustainability profile. Investing in modern, energy-efficient capping machines can yield significant returns over their lifetime.

**Tip:** Look for machines that come with energy-saving certifications or technologies, as these often lead to better performance and reduced costs in the long run.

When selecting a bottle capping machine, it's essential to consider not just the basic functionality, but also the space requirements of your production area. A compact design can be invaluable, especially in facilities with limited floor space. Assessing your layout will help you choose a machine that fits seamlessly while still allowing room for operators to work efficiently. Moreover, some machines offer modular designs that can be expanded or adjusted depending on your production volume, making it easier to adapt as your business grows.

Maintenance is another crucial factor that influences the longevity and performance of your capping equipment. Look for machines that offer easy access to internal components, simplifying routine maintenance tasks. Regular upkeep, including cleaning and lubrication, can prevent costly downtime and extend the lifespan of your machinery. Furthermore, consider the availability of customer support and replacement parts; a reliable manufacturer can provide necessary assistance and minimize the impact of any machine-related issues. Lastly, versatility in capping solutions is key. Opt for machines that can handle various cap types and sizes, allowing you to diversify your product offerings without the need for multiple specialized machines. This flexibility can significantly enhance your production efficiency and responsiveness to market demands.

| Capping Machine Type | Production Speed (Bottles/Min) | Space Required (Sq. Ft.) | Maintenance Frequency | Versatility (Types of Caps) |

|---|---|---|---|---|

| Semi-Automatic Capping Machine | 20-30 | 50 | Weekly | Screw Caps, Corks |

| Fully Automatic Capping Machine | 50-100 | 80 | Monthly | Screw Caps, Snap Caps, Corks |

| Electric Capping Machine | 30-60 | 60 | Bi-weekly | Screw Caps, Dropper Caps |

| Manual Capping Machine | 5-15 | 30 | As needed | Screw Caps |

| Rotary Capping Machine | 100-200 | 100 | Quarterly | Screw Caps, Specialty Caps |

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm