Choosing the right Rolling Packaging Film is essential for various industries. According to a recent report by Smithers Pira, the global packaging film market is expected to reach $300 billion by 2025. Such growth emphasizes the importance of understanding specific needs.

Dr. Jane Reynolds, an expert in the packaging sector, highlighted, “Selecting the correct film can significantly impact product preservation and shelf appeal.” This underscores the responsibility manufacturers face. They must balance durability, cost, and environmental impact when choosing materials.

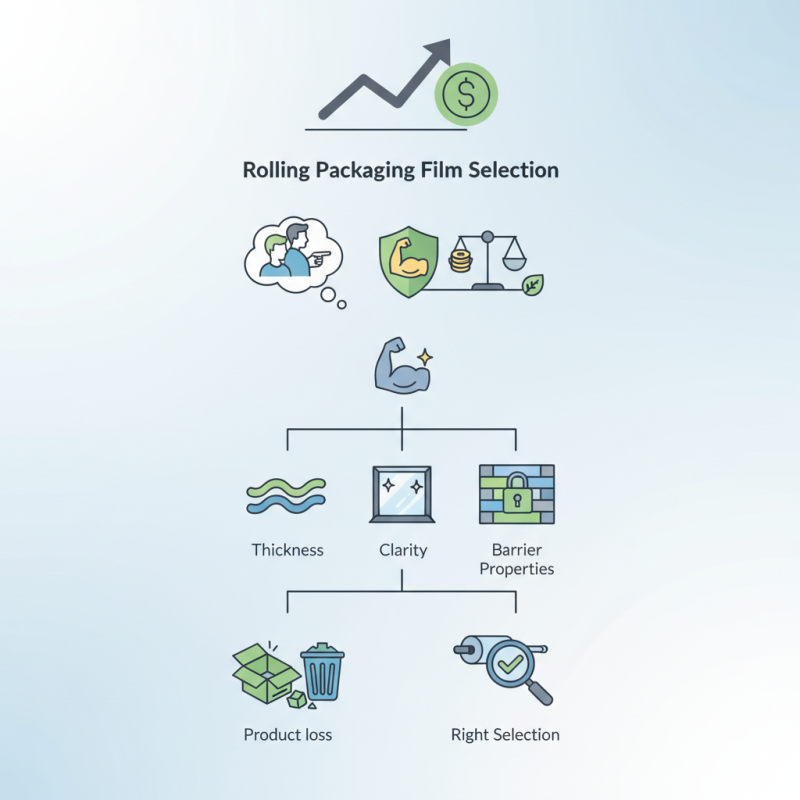

Yet, navigating options can be challenging. With numerous types available, decision-making can lead to frustration. Factors such as thickness, clarity, and barrier properties must be evaluated. Choosing poorly could result in product loss or increased waste. Therefore, investing time in research is crucial for the right selection in Rolling Packaging Film.

When selecting rolling packaging films, it's crucial to understand the types available. Various materials serve different purposes. For instance, polyethylene (PE) films are common due to their durability and flexibility. A report by Smithers Pira notes that this segment accounts for over 30% of global flexible packaging usage.

Another popular choice is polypropylene (PP) film. It offers better clarity and is ideal for packaging products that require visibility. This material's market share is steadily increasing, with studies projecting a growth rate of around 4.5% annually through 2027.

However, challenges exist. Each film type has limitations, such as their resistance to specific temperatures or environmental factors. Many films are not suitable for all products. Companies often face difficulties when determining the right film for their needs. Data from the Flexible Packaging Association indicates that 40% of businesses struggle with material compatibility, highlighting the importance of careful selection.

The process of choosing the right rolling film demands attention. By understanding each type's characteristics and potential drawbacks, businesses can improve their packaging strategies.

When selecting a rolling packaging film, understanding your requirements is crucial. What products will you be packaging? Different materials can affect the final outcome. For example, food items may need specific barrier properties. On the other hand, consumer goods may focus on aesthetics. Each choice impacts functionality and appearance.

Consider your objectives for packaging. Are you aiming for durability, flexibility, or environmental sustainability? Always think about the conditions your product will face. For instance, if it needs protection during shipping, a strong film is essential. However, if the emphasis is on visual appeal in a retail setting, a clear, glossy film could be more suitable.

It's important to reflect on your decision-making process. Sometimes, the perfect film may not exist. You might find that compromises are necessary. Understanding your priority areas can help navigate these challenges. Assessing all these factors will lead to a more informed choice, ultimately benefiting your product and its presentation.

Choosing the right rolling packaging film can significantly impact your product’s shelf life and visual appeal. Evaluating the key properties of these films is essential. Thickness, for instance, plays a crucial role. According to recent industry reports, films ranging from 30 to 50 microns are popular for food packaging, while 70 microns or thicker is often used for industrial applications.

Another important property is barrier performance. Films need to protect contents from moisture and oxygen. A study from the Packaging Technology Institute states that about 30% of products degrade because of poor packaging. This statistic highlights the necessity of selecting films that meet specific barrier requirements. Transparency is also vital for product visibility. Shoppers often prefer products they can see. Yet, too much clarity can expose contents to light, causing degradation.

Many users overlook the film’s heat sealability. It is crucial for maintaining a tight seal during packaging processes. If seal integrity fails, product waste increases. A report by the Flexible Packaging Association warns that poor seals can lead to up to 20% product loss in some industries. Each of these properties requires careful consideration and reflection on how they align with specific packaging needs.

When selecting rolling packaging films, cost-effectiveness and durability are crucial factors. According to industry reports, the average cost of polyethylene rolls ranges between $2.50 to $4.00 per pound. This price significantly impacts production budgets. For many businesses, balancing cost and functionality becomes a tightrope walk.

Durability varies widely among different film types. For instance, cast films often provide excellent clarity but may be less resistant to punctures. Conversely, blown films are thicker and more robust, which enhances their durability. A report by the Flexible Packaging Association indicates that blown films can withstand stress better than their cast counterparts. Yet, they come at a higher price point, making the choice complex.

It’s also essential to consider specific application needs. Not every film suits every product. Some films might offer great oxygen barrier properties but may not seal well in humid conditions. Reflections on production processes reveal many facilities still struggle with consistent sealing. Thus, figuring out the right film requires a careful evaluation of both performance requirements and budget constraints. Balancing these can be challenging, but it’s vital for long-term success in packaging.

Choosing the right rolling packaging film is essential for operational efficiency and product protection. However, selecting the right supplier is equally critical. Research shows that nearly 70% of businesses face challenges due to improper supplier choice. A lack of due diligence often leads to increased costs and reduced quality.

When sourcing suppliers, consider their track record. Look for reviews and testimonials from businesses similar to yours. Visit their facilities if possible. This helps you gauge their production capacity and quality control processes. A reliable supplier should offer comprehensive support, including technical expertise and responsive communication.

Here are a few tips for choosing a supplier:

- Prioritize suppliers with certifications. This ensures compliance with industry standards.

- Request samples before committing. Evaluate the quality and performance of their films in real-world conditions.

- Establish clear expectations upfront. Miscommunication can lead to delays and frustration.

| Film Type | Material | Thickness (microns) | Application | Key Features |

|---|---|---|---|---|

| Stretch Film | LDPE | 15-50 | Pallet Wrapping | High Elasticity |

| Shrink Film | PVC, PE | 30-200 | Product Bundling | Tamper-Resistant |

| Barrier Film | EVA, Nylon | 50-100 | Food Packaging | Moisture & Oxygen Barrier |

| Wrap Film | Polyester | 20-75 | Retail Packaging | High Clarity |

| Vacuum Film | PA, PE | 50-120 | Food Preservation | Extended Shelf Life |

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm