In the rapidly evolving landscape of modern manufacturing, efficiency has become a cornerstone of operational success, particularly within the realm of liquid packaging. One prominent innovation driving this efficiency is the Paste Filling Machine, a specialized apparatus designed to streamline the filling process of viscous substances across various industries. These machines not only enhance production speeds but also significantly reduce waste and enhance precision, ensuring that each product meets quality standards. As manufacturers strive to optimize their processes and remain competitive, understanding the benefits and operational capabilities of Paste Filling Machines is essential. This blog will delve into their efficiency metrics, explore the latest advancements in technology, and highlight best practices for integrating these machines into contemporary production lines, ultimately showcasing how they are reshaping the manufacturing landscape.

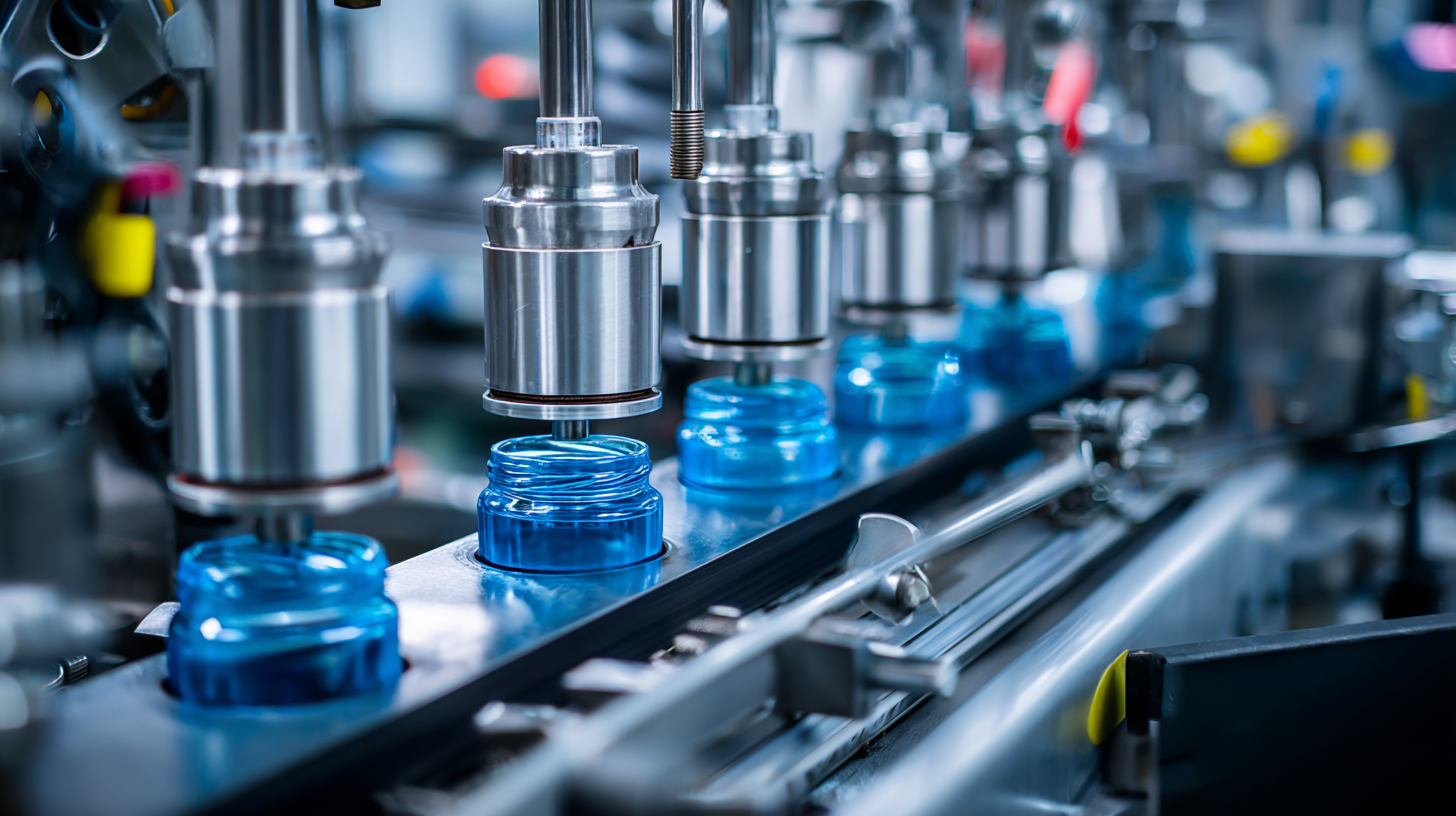

Paste filling machines play a crucial role in modern manufacturing processes, particularly in industries such as food, pharmaceuticals, and cosmetics. These machines are specifically designed to handle viscous products, ensuring precision and efficiency during the filling process. According to a report by Smithers Pira, the global market for paste filling machines is expected to grow by 6% annually, reaching an estimated value of $1.7 billion by 2025. This surge in demand is largely driven by the increasing production of sauces, creams, and adhesives that require accurate filling mechanisms to maintain product integrity.

In addition to precision, paste filling machines enhance manufacturing efficiency by reducing cycle times and minimizing waste. A study published in the Journal of Manufacturing Processes emphasizes that automated filling systems can achieve up to 98% accuracy, significantly lowering the risk of overfilling or underfilling products. With the integration of advanced technology, such as smart sensors and AI algorithms, these machines are capable of adapting to different product viscosities, resulting in optimized flow rates and consistent filling volumes. As industries continue to adapt to rapid changes in consumer demand, paste filling machines are proving to be an indispensable asset in streamlining production lines and improving overall product quality.

The efficiency of paste filling machines in modern manufacturing processes is critical for optimizing production output and minimizing waste. Key efficiency metrics for evaluating these machines include fill accuracy, cycle time, and operational capacity. Recent studies have shown that advanced machine learning techniques can significantly enhance the predictive capabilities of such systems, allowing manufacturers to optimize their operations. For instance, a study found that using ensemble machine learning to evaluate the wet carbonation process of recycled cement paste could improve calcium carbonate yield, effectively demonstrating the intersection of technology and process efficiency in modern manufacturing.

To boost the efficiency of paste filling machines, it's essential to regularly assess their fill accuracy. Machines should achieve at least 99% fill accuracy to minimize product waste and ensure quality control. Moreover, reducing cycle time is crucial; manufacturers should aim for a cycle time that allows for the filling of 100-200 units per hour, depending on the product's viscosity.

**Tips:** Regular maintenance and calibration of paste filling machines can significantly enhance their accuracy and longevity. Investing in advanced data analytics can provide insights into operational bottlenecks and guide process improvements. Lastly, training operators on the latest technologies can lead to better handling of equipment and ultimately an increase in overall efficiency.

In modern manufacturing processes, the efficiency of paste filling machines is significantly enhanced by innovative technologies, particularly advancements in heat control mechanisms. A notable innovation is the MR-MUF technology, which has transformed heat dissipation in chip packaging. Research indicates that effective heat management can increase the lifespan and performance of chips by up to 30%, thus directly impacting the productivity and reliability of manufacturing lines. This breakthrough allows manufacturers to operate at higher speeds without compromising the quality or integrity of the product.

Moreover, the emphasis on sustainability has led to the development of biodegradable biopolymers from seafood waste, which presents an eco-friendly alternative for food packaging materials. According to industry reports, the global market for biodegradable packaging is expected to reach $414 billion by 2027, driven by consumer demand for sustainable solutions. By integrating such materials into paste filling processes, manufacturers not only enhance the efficiency of their operations but also contribute to reducing environmental impact, aligning with contemporary values of sustainability and innovation in manufacturing.

In the rapidly evolving landscape of manufacturing, the choice of filling method is critical for optimizing efficiency and product quality. Paste filling machines have gained prominence, particularly in sectors like food, pharmaceuticals, and cosmetics. Unlike traditional filling methods, which often rely on gravity or pressure, paste filling specializes in handling viscous products, offering greater precision and reduced waste. This accuracy allows manufacturers to maintain stringent quality control standards and to cater to varying product viscosities with ease.

When comparing paste filling to other methods, such as volumetric or time-based filling, several advantages emerge. Paste fillers deliver a higher level of customization, as they can be adjusted to accommodate different filling speeds and quantities seamlessly. Moreover, they are less prone to product spillage, which not only conserves material but also minimizes clean-up time and cost. As industries demand more from their production lines, the efficiency of paste filling machines stands out, proving essential for meeting both consumer expectations and regulatory requirements.

In today’s fast-paced manufacturing environment, optimizing the use of paste filling machines is essential for enhancing productivity and maintaining product quality. One of the best practices involves regular maintenance and calibration of the machines. Ensuring that the machines are in optimal condition not only reduces the risk of malfunctions but also improves the accuracy of filling, thereby minimizing waste and ensuring consistency in production. Implementing a routine maintenance schedule can significantly extend the lifespan of the equipment and enhance overall operational efficiency.

Another crucial practice is to train operators thoroughly on the machine's functionality and best operational techniques. Knowledgeable staff can quickly troubleshoot minor issues, making real-time corrections that prevent production delays. Additionally, leveraging technology, such as automatic monitoring systems, can provide valuable insights into the filling process, allowing for timely adjustments. By continuously analyzing performance data, manufacturers can identify trends and optimize filling parameters, ensuring that paste filling machines operate at peak efficiency.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm