In the ever-evolving landscape of packaging technology, choosing the right bottle labeler is crucial for businesses aiming to optimize their production processes and enhance brand visibility. According to a recent report by MarketsandMarkets, the global labeling equipment market is projected to grow from $4.5 billion in 2020 to $6.9 billion by 2025, highlighting a significant increase in demand for efficient labeling solutions. This growth underscores the importance of integrating high-quality equipment that aligns with specific operational needs.

Expert insights reveal the impact of selecting the appropriate bottle labeler on overall production efficiency. John Smith, a renowned packaging industry expert and author of "The Future of Labeling Technologies", emphasizes, “The right bottle labeler not only improves productivity but also plays a vital role in maintaining product integrity and enhancing consumer appeal.” With various types of labelers available, including pressure-sensitive, shrink sleeve, and wrap-around, understanding the unique requirements of your business is essential.

By carefully considering factors such as label type, production speed, and scalability, manufacturers can ensure they invest wisely in labeling solutions that will support their growth and branding strategies.

When choosing a bottle labeler for your business, the first step is to thoroughly analyze your labeling needs based on your product specifications and production requirements. Consider the size, shape, and material of your bottles, as these factors can significantly influence the type of labeling equipment you will need. For example, a high-speed production line with varied bottle shapes may require a more versatile and adaptive labeler, while a lower-volume operation with standardized bottles could benefit from a simpler, cost-effective solution.

Additionally, the environment in which the labeler will operate is crucial. Assess aspects such as ambient temperature, humidity levels, and the possibility of dust or contaminants, as these can affect the labeling process and the performance of the machine. Furthermore, think about your production goals—whether you prioritize speed, accuracy, or flexibility—and ensure that the labeler aligns with these objectives. By aligning your equipment selection closely with your specific labeling needs, you can enhance operational efficiency and product presentation.

When selecting a bottle labeler for your business, understanding the distinction between manual and automatic labeling options is crucial. Manual labeling systems often represent a lower upfront investment and are ideal for small-scale operations with limited production volumes. According to a report by Grand View Research, the manual labeling segment is projected to grow at a rate of 4.5% annually due to the increasing preference among startups and artisanal producers who prioritize flexibility and cost-effectiveness. These systems allow for quick adjustments and are suitable for businesses that require customization without a massive scale.

On the other hand, automatic labeling systems provide significant advantages for larger operations. They can drastically increase production speeds—up to 200 labels per minute—thus significantly reducing labor costs and human error (Packaged Facts report). Given that more than 75% of consumers are influenced by packaging when making a purchase, investing in automatic labelers can improve overall efficiency while ensuring high-quality, consistent labeling that meets industry standards. As businesses grow, transitioning to automatic systems may become essential for maintaining competitive advantage and meeting increasing market demand.

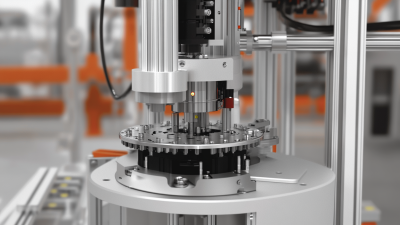

When selecting a bottle labeler for your business, one crucial factor to consider is

labeling speed and efficiency. In fast-paced production environments, the labeling process must harmonize with overall production goals.

For instance, if your business is in the beverage industry, which is projected to grow significantly, with global pump and dispenser market values reaching $171.9 billion by 2024,

a labeler that can keep up with such demand is vital. The right machine can enhance not only productivity but also reduce downtime, ensuring that your operations meet

demanding market requirements.

Efficiency in labeling is about more than just speed; it is also about

accuracy and reliability. A high-performance labeler can drastically reduce errors, ensuring that

each product is correctly labeled before reaching the customer. As industries look to optimize processes, tools that enable

seamless integration into existing workflows are becoming increasingly important.

Advanced labelers equipped with smart technologies can analyze production speeds

and adjust in real-time, thus maintaining the pace needed to achieve scale without compromising on quality. This adaptability is essential,

especially as production goals evolve in a dynamic marketplace.

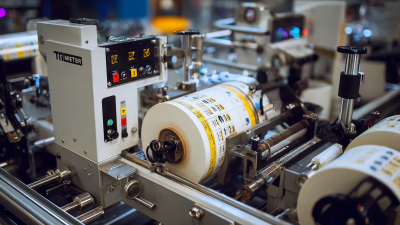

When it comes to choosing the right bottle labeler for your business, assessing label compatibility is crucial. Different bottle types may require specific label materials or adhesive types to ensure that labels adhere properly and resist wear over time. According to a report by Smithers Pira, the global label market is expected to reach $75 billion by 2024, highlighting the importance of high-quality labels in maintaining brand integrity across various beverage categories. Understanding your bottle materials—glass, plastic, or metal—can significantly influence the label choice and application technique.

Here are a couple of essential tips to consider when selecting the right labeler for your business. First, evaluate the labeling machine's capabilities concerning the range of bottle shapes and sizes you plan to use. Ensuring that it can handle both standard and custom bottles will save you time and resources in the long run. Additionally, consider the type of label material that is best suited for your products. For instance, cold beverages might require waterproof labels, while products intended for ambient storage may not need the same level of durability.

Lastly, verify the machine's compatibility with your existing production line. A seamless integration will streamline your labeling process and reduce downtime. By prioritizing label compatibility and the right technical specifications, businesses can enhance their production efficiency and product presentation, ultimately improving customer satisfaction and sales.

When selecting the right bottle labeler for your business, budget considerations play a crucial role in striking a balance between cost, functionality, and features. Understanding the range of prices available is essential. Basic labelers can be affordable, while high-end models equipped with advanced technology may require a more substantial investment. It’s vital to determine the specific needs of your business, such as production volume and label design complexity, to find a model that meets those demands without overspending.

Additionally, examining the various styles and floor plans of different labelers can influence your purchasing decision. Some machines are designed for compact spaces, while others might offer larger configurations to handle higher output. It’s important to consider how the labeler will fit into your production line, as this can affect workflow efficiency. By weighing these considerations alongside your budget, you can make an informed choice that enhances your operations while keeping costs in check.

| Labeler Type | Cost Range | Functional Features | Ideal For |

|---|---|---|---|

| Manual Label Applicator | $100 - $500 | Simple operation, portable | Small businesses, low volume |

| Semi-Automatic Labeler | $500 - $2,000 | Higher speed, more adjustment options | Medium volume producers |

| Fully Automatic Labeler | $2,000 - $10,000 | High efficiency, integrates with other systems | High volume production lines |

| Wrap-around Labeler | $1,000 - $5,000 | Circular labeling for bottles | Beverage manufacturers |

| Clear Label Applicator | $750 - $3,000 | For transparent labels, minimal visibility | Aesthetic-focused businesses |

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm