In the ever-evolving world of beverage and packaging industries, the selection of the right Bottle Capping Machine plays a pivotal role in ensuring efficiency and product integrity. According to a recent report by Market Research Future, the global bottle capping machine market is projected to reach a valuation of over $2 billion by 2025, driven by the growing demand for packaged beverages and the need for automated solutions in manufacturing. With manufacturers increasingly prioritizing quality control and operational efficiency, understanding the features and functionalities of various capping machines becomes essential. This blog post aims to equip business owners with five essential tips that will aid them in selecting the most suitable Bottle Capping Machine, ensuring that it meets their production needs while also enhancing the overall packaging process.

When selecting a bottle capping machine for your business, several key factors must be taken into account to ensure optimal performance and efficiency. First and foremost, it’s essential to consider the machine's compatibility with your bottle types and sizes. Different industries utilize various bottle shapes, so understanding the specific requirements of your products is crucial. A versatile machine that can handle a variety of bottles will offer greater flexibility and reduce the need for multiple machines, ultimately saving costs and space.

Another critical aspect is the production speed of the capping machine. Evaluate the demand and packaging throughput of your operation to choose a machine that can keep pace with your production line. A faster machine may boost overall productivity, but it should not compromise the quality of the seal. Additionally, consider the ease of operation and maintenance. Machines that are user-friendly and require minimal downtime for maintenance will enhance efficiency and reduce training time for new operators, contributing to a seamless workflow within your facility.

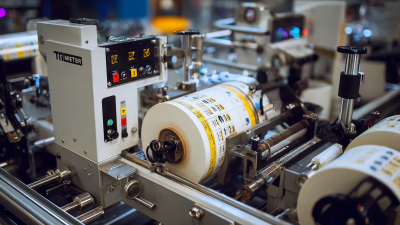

When selecting a bottle capping machine, it's crucial to understand the various types available on the market. Each machine is designed to cater to specific production needs and bottle types, making it essential for businesses to choose the right fit. The most common types include roll-on capping machines, which apply a cap by rolling it down onto the bottle, producing a tamper-evident seal ideal for beverages and pharmaceuticals. Then there are snap-on capping machines, best suited for lightweight caps used in consumer products, allowing for quick and efficient sealing.

Another important type is the spindle capper, which tightens screw caps onto bottles using a spinning motion. This machine is well-suited for products with a high level of viscosity, such as oils or sauces. For businesses that require versatility, there are also automatic capping machines that can handle multiple bottle sizes and cap types, adapting easily to varying production demands. By understanding these different types, companies can ensure they invest in a bottle capping machine that aligns perfectly with their operational goals and product requirements.

When selecting a bottle capping machine, evaluating your production needs is crucial to finding the right capacity. Understanding your current output and future production goals will help you choose a machine that not only meets your immediate requirements but also accommodates growth. Begin by analyzing your average daily production volume and peak demand times. This assessment enables you to determine the optimal capping speed and machine features that align with your workflow.

Additionally, consider the types of bottles and caps you will be using. Different products may require varying levels of torque or specific capping mechanisms. Reviewing your bottle's specifications, including diameter and material, paired with your production goals will guide you toward a machine designed for efficient operation. Investing time in these evaluations ensures that you select a capping machine that enhances productivity, reduces downtime, and fulfills your business's unique demands, ultimately paving the way for operational success.

When choosing the right bottle capping machine for your business, it is crucial to focus on several important features that differentiate high-quality equipment from inferior options. First and foremost, consider the machine's versatility; a high-quality capping machine should accommodate various bottle sizes and cap types. Research indicates that businesses utilizing versatile capping solutions can enhance productivity by up to 30%, streamlining their packaging processes and ultimately leading to increased profitability.

Another critical feature is automation capability. Many modern capping machines are equipped with advanced technology that allows for automated adjustments and operation, which significantly reduces manual labor and minimizes production errors. For instance, industry studies show that automated capping systems can reduce labor costs by as much as 15%, making them an attractive investment for any business looking to improve efficiency. Additionally, durability and reliability should not be overlooked; investing in a robust capping machine ensures long-term operational stability and decreases the likelihood of breakdowns, which can disrupt production timelines and incur additional expenses.

By emphasizing these essential features, businesses can make an informed decision when selecting a bottle capping machine that not only meets their current needs but also supports growth in an evolving market landscape.

| Feature | Importance | Consideration |

|---|---|---|

| Capping Speed | Determines how quickly you can fill and seal bottles | Choose based on your production demands |

| Type of Caps | Compatibility with various bottle and cap sizes | Ensure machine fits your specific cap types |

| Automation Level | Impact on labor costs and efficiency | Consider semi-automatic vs. fully automatic options |

| Durability | Influences long-term maintenance costs | Look for high-quality materials and construction |

| Ease of Use | Affects training time and operational efficiency | Choose user-friendly designs and controls |

When it comes to selecting a bottle capping machine for your business, budgeting wisely is crucial. According to a recent industry report from Grand View Research, the global beverage packaging machinery market is expected to reach $21.09 billion by 2025, fueled by increasing demand for high-quality packaging solutions. This statistic underscores the importance of investing in reliable machinery that not only fits your budget but also offers durability and efficiency.

Balancing cost and quality requires a thorough evaluation of your needs and the specific capabilities of different machines. For instance, opting for a machine that might seem cheaper initially could lead to higher long-term costs due to frequent repairs or inefficiency in handling volatile products. The PMMI’s 2021 State of the Industry report highlights that 60% of manufacturers consider the total cost of ownership—factoring in maintenance and operational efficiencies—when deciding on machinery. Thus, while staying within budget is essential, prioritizing quality will ultimately safeguard your production line and ensure better profitability in the long run.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm