In the dynamic landscape of manufacturing and packaging, the choice of a Filling Machine can significantly influence a business's operational efficiency and product quality. According to a recent industry report from Grand View Research, the global filling equipment market is expected to reach $5.6 billion by 2025, growing at a CAGR of 4.7%. This growth is indicative of the increasing demand for automation and precision in filling processes, which are critical to meeting both consumer expectations and regulatory standards.

Industry expert Dr. James H. Miller, a leading consultant in packaging technology, emphasizes the importance of selecting the right filling machine by stating, "Choosing the appropriate filling equipment is not merely a purchasing decision; it is a strategic investment that can optimize production efficiency and ensure product integrity." As businesses navigate this crucial decision, understanding the various types of filling machines available—each with distinct functionalities and best-use scenarios—becomes essential. This guide will explore seven essential tips that can aid in making an informed decision tailored to your specific operational needs and business goals, ensuring you select a Filling Machine that aligns with your company's vision for growth and quality.

When it comes to selecting the right filling machine for your business, understanding your specific needs is paramount. Every industry has unique specifications that dictate the type of filling equipment required. Start by assessing the volume of production your business requires. High-output operations may need fully automated systems, while smaller businesses might benefit from semi-automated or manual options. Additionally, consider the type of product you will be filling—liquids, powders, or granules all demand different technologies and mechanisms.

Another crucial factor is the scalability of the filling machine. As your business grows, your equipment should be able to accommodate increased production demands without necessitating a complete overhaul. Evaluate the machine's flexibility in handling different product sizes and packaging formats, as this adaptability can enhance your efficiency and productivity over time. Moreover, take into account the availability of after-sales support and maintenance services, which are essential for ensuring consistent operation and minimizing downtime in your production line. By carefully analyzing these aspects, you can make an informed decision that aligns with both your current operational needs and future growth plans.

| Tip Number | Tip | Key Considerations |

|---|---|---|

| 1 | Understand Your Product | Liquid viscosity, temperature, and filling volume |

| 2 | Determine Filling Speed | Production rate and operational efficiency requirements |

| 3 | Consider Container Types | Bottles, pouches, jars, or custom containers |

| 4 | Evaluate Automation Level | Manual, semi-automatic, or fully automatic systems |

| 5 | Budget Considerations | Initial investment vs long-term savings |

| 6 | Maintenance and Support | Availability of technical support and parts |

| 7 | Seek User Reviews | Feedback from current users and industry reputation |

When it comes to selecting a filling machine for your business, understanding the different types available is essential to ensure that you choose one that suits your product perfectly.

The main types of filling machines include liquid, powder, and granule fillers, each designed to handle their specific materials with precision.

Liquid filling machines can be subdivided into volumetric and gravimetric options, providing flexibility depending on the viscosity of your products.

On the other hand, powder fillers are typically employed in the packaging of food, pharmaceuticals, and cosmetics, while granule fillers excel in environments where small solid items need to be dealt with efficiently.

To make an informed decision, consider these essential tips.

First, analyze the characteristics of your product — whether it's thick, thin, or granular — as this will significantly influence the type of machine required.

Second, think about the production scale and throughput needed for your business.

Some machines might be slower but offer precise filling for smaller batches, while others could handle high-volume output but compromise on precision.

Lastly, review your budget, keeping in mind not just the initial cost, but also maintenance and operational expenses over time.

Ultimately, finding the right filling machine can streamline your operations and enhance product quality, ensuring that your business remains competitive in the market.

When selecting a filling machine for your business, understanding the key features to look for is crucial to ensuring efficient production and optimal performance. One of the primary considerations should be the machine's filling accuracy. Precision is essential, especially for industries dealing with valuable or sensitive products. Look for machines equipped with advanced technology that minimizes fluctuations in fill weights, ensuring that each container is filled correctly while reducing material waste.

Another important feature is the machine's versatility. A filling machine that can accommodate various container sizes and types—such as bottles, pouches, or jars—will provide your business with the flexibility to adapt to changing product lines. Additionally, consider the machine's ease of operation and maintenance. User-friendly interfaces and straightforward cleaning processes can significantly reduce downtime and training costs, making your production more efficient. Ultimately, opting for a filling machine with these essential features will help streamline your operations and enhance the overall productivity of your business.

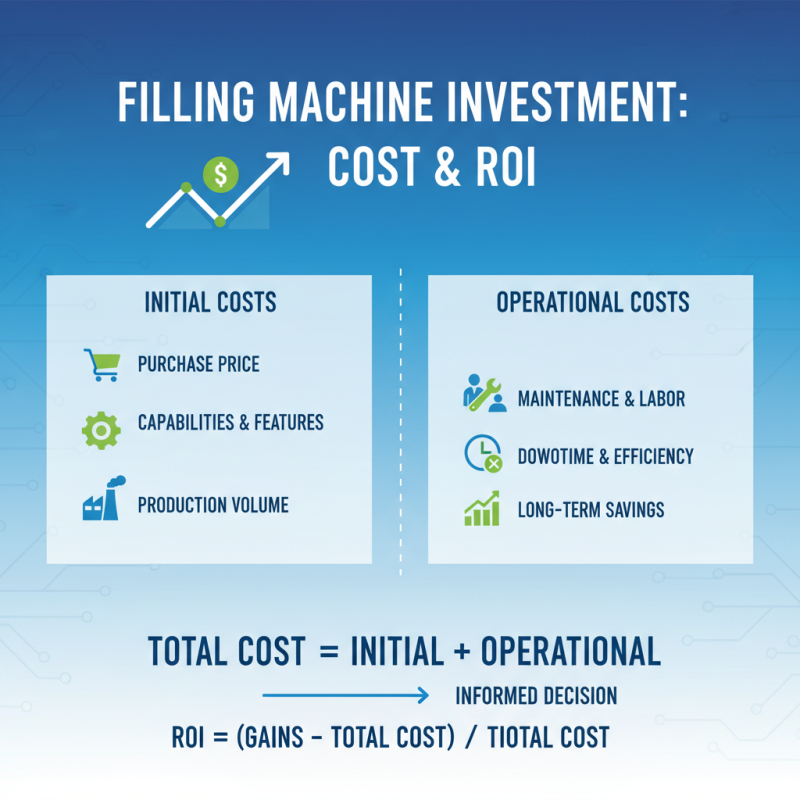

When investing in a filling machine for your business, evaluating the cost and return on investment (ROI) is crucial for making an informed decision. The initial expenditure on a filling machine can vary significantly based on its capabilities, features, and the volume of production it supports. It’s essential to analyze not just the purchase price, but also the long-term operational costs, including maintenance, labor, and potential downtime. A comprehensive understanding of these costs can help identify whether the machine aligns with your financial constraints and production goals.

Additionally, calculating the ROI involves forecasting the increased efficiency and productivity the machine will bring to your operations. A more efficient filling machine can reduce labor costs, minimize material waste, and increase output. As such, businesses should assess how quickly they can expect to recoup their investment based on projected sales and the expected increase in productivity. By comparing these financial projections against the costs, you can make a more strategic choice that supports both immediate and future growth objectives. This approach not only aids in selecting the right machine but also ensures that the investment contributes positively to your bottom line.

When investing in a filling machine for your business, maintenance and support are critical aspects that can greatly influence the longevity and efficiency of your equipment. Regular upkeep ensures that the machine operates at peak performance, minimizing the likelihood of unexpected breakdowns that can lead to costly downtimes. Establishing a consistent maintenance schedule helps identify potential issues before they escalate, allowing for timely interventions. Furthermore, understanding the machine's operational needs enables businesses to create a conducive environment that enhances durability.

In addition to routine maintenance, having a reliable support system in place is essential. This includes access to technical expertise and swift assistance in case of malfunctions. Choosing a supplier that offers comprehensive support services can make a significant difference. Quick and efficient customer service not only reduces response times for repairs but also provides valuable resources such as training for operators. By prioritizing maintenance and robust support, businesses can ensure that their filling machines remain reliable assets that contribute to operational efficiency and productivity over time.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm