An extensive demand for efficient and reliable Automatic Filling Machines exists across the industries in the rapidly evolving manufacturing world. According to a recent report by Global Market Insights, the automatic filling machine market is forecast to exceed $7 billion before 2026, fueled by the increased thirst for automation across a variety of industries such as food and beverage, pharmaceuticals, and cosmetics. Such rapid growth highlights the importance of a deep supply chain consisting of quality suppliers who can provide such advanced technology and custom solutions, which will eventually add value to both operational efficiency and product quality.

Locating excellent suppliers for Automatic Filling Machines is very vital for companies to maintain competitiveness in an overcrowded market. The more complete the supplier evaluation process, the better positioned the company will be to select filling machine suppliers that engage in good manufacturing practices and complement its specific operational needs. This trend was also corroborated by Technavio, with the expectation for the world filling machinery market to continue outpacing 5% CAGR in the period between 2021 and 2025, establishing a growing need for strategic partnerships with trustworthy suppliers. In this blog, we will discuss some of the most important criteria and best practices in searching for suppliers that are poised to give a major contribution to your production success and sustainability.

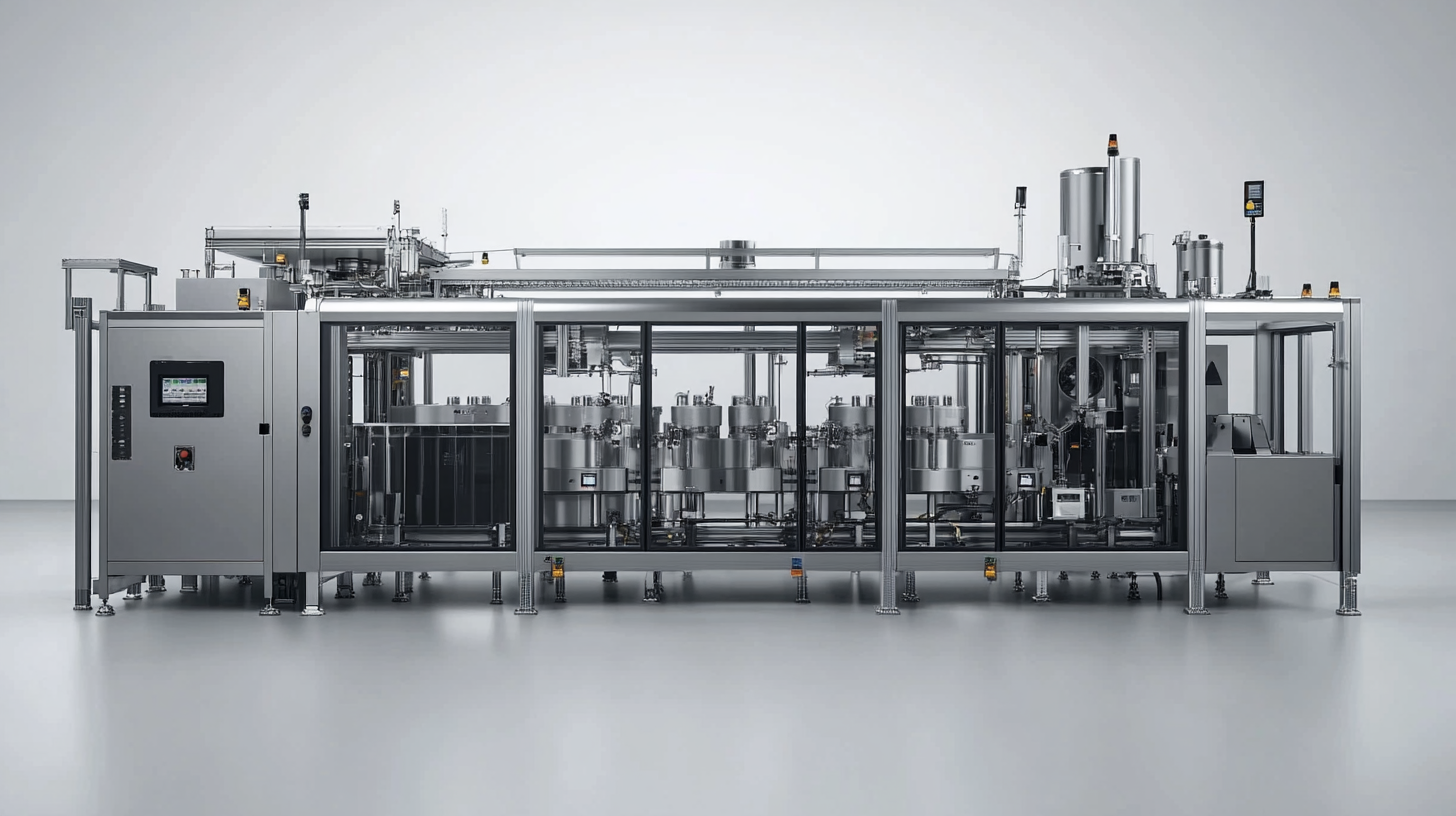

Your understanding of your specific requirements should come first in the selection of automatic filling machines for your production line. The market for liquid filling machines is vast, with many products for different industry segments such as food and beverage, pharmaceuticals, and cosmetics. The in-depth analysis of market sizes, shares, and trends confirms a strong shift toward automation supported by the need for greater efficiency and consistency in production. When it comes to machine functionality, choosing between automatic and semi-automatic systems should be considered. Thanks to rapid output and precision, in general, automatic machines will be preferred for heavy-duty production. However, semi-automatic systems may provide some cost advantages for smaller operations or products with lower demand. Price will also depend on the packaging material types to be incarnated, such as glass, plastic, TETRA Packaging, and cartons, since each material requires specific requirements that affect filling technology choice. How you choose to fill also becomes a crucial decision. Each of the filling systems—vacuum filling, volumetric filling, and weigh filling—has its added advantages, depending on the viscosity and nature of the liquid being handled. Knowing these details will allow you to pick a machine that is in tune with your production requirements as well as one that is appropriate to market standards and regulatory compliances. So take your time to weigh all these options since they will ultimately govern the fate of your filling operations.

Supplier credibility verification forms a major part of successful sourcing of an automatic filling machine from the supplier. The first way is to assess the supplier's experience in this line of business such as the history of the supplier with how long it has been in operation and what products it has been producing. Such a supplier is thus more likely to be able to handle any needs one may have. Suppliers who have previously dealt with clients in the industry should be researched since they are more likely to have insights regarding some nuances regarding specifications.

Last, one also assesses reviews and testimonials from previous customers of the supplier as another dimension of supplier credibility verification. You will hear reliable info about the supplier-not reliance on reviews from online platforms, industry forums, or social media but also the information drawn from other companies as witnesses to what they say regarding customer service, product quality, and post-sale support. Also, evaluate ratings from some reputable industry websites so that you can check how the supplier is positioned in the market.

Pearl certificates and membership in industry associations also provide credible proof for the supplier. Every supplier with such as a certification means that he is often seen to be following a certain set of quality standards to deliver. Likewise, belonging to industry associations indicates a supplier's concern for keeping himself abreast with the new development in technology as well as market trends. Presumably, with such consideration, one will be able to assess how a supplier can meet operational requirements so that it can act in a more informed decision-making purchase.

Looking out for specific indicators that help identify some reliable suppliers is considering the quality of automatic filling machines. As a point, they must carry out a thorough inspection of the produced items above and below the level of production. A reputable supplier would rather have a well-defined process for quality inspection, ensuring each machine meets established industry standards. Look for suppliers who can provide detailed reports accounting for their testing mechanisms, for example, stress tests and performance evaluations. This sign would indicate well a supplier that puts value above all else.

Another important consideration relates to customer feedback and references. A trustworthy supplier will be the one to deliver good reviews and case studies from previous clients. Such endorsements could be very useful in revealing the reliability of these machines and the performance in their real-life applications. Such conversations could also reveal the shadow side of the machines and identify areas they score well in.

More importantly, the materials and components used in filling machines also appear to be extremely important to the durability and efficiency of these machines. Suppliers who claim to source their parts high-grade and comply with the industry specification would be more likely to design machines that could withstand the rigors of different production environments. Further investigations into the supply of the supplier as well as his partnership with those manufacturing components will guarantee the quality of the machine.

Last, but not least tell-tales, is commitment of the supplier to the whole approach-rather than the one-time supplying for a good-quality filling machine. A supplier oriented toward futuristic development of the filling machine is certainly going to invest in R&D and short time will end up providing some high-tech applications obviously going to reduce the downtime with machines thus increasing their productivity as a whole. Such suppliers became quite telling from the beginning; these are very often suppliers who want to retain their name in the market with the reliability being offered through efficient products.

With sourcing automatic filling machines, pricing and the specifications of machines are just a couple of business' focuses. However, one pertinent aspect often overshadowed is after-sales service. After all, it's a machine, and the after-sales service is what counts. An outstanding after-sales support will save the spouse time and money, averting any interruptions to his process as a result of such unforeseen delays.

True after-sales service will include troubleshooting, maintenance, and parts replacement. The manufacturers of machines giving due importance to after-sales service train prospective users in the operation of the equipment. They make sure support continues to help their customers resolve any unexpected issues that can arise after their machine's installation. Potential machine downtimes have adverse effects on a company's financial health, and this whole dynamic can either help keep the down-time to a minimum or aggravate it. For this reason, it is imperative to evaluate the supplier's customer service team to see how responsive and knowledgeable that team is, especially on the company's most serious occasions.

An after-sales service strengthens the supplier-client bond. This rapport fosters collaborative spirit, allowing free communications, which translate into improvements and innovations in the equipment. Businesses should therefore consider customer support well while evaluating suppliers, as the presence or absence of it may become an instrumental factor in deciding the long-term satisfaction and success of operations.

Thus, in today's competitive arena, well-heeled clients are looking for top suppliers of automatic filling machines; however, getting to know their pricing mechanism without compromising quality could be an art. And up to this point, recent market trends have seen quite a drastic shift in the pricing logic wherein a number of industries are engaging in a default price war to wheedle consumers into opting for their products. This scenario impacts not only classical markets but goes all the way to the beaders of the supply line where at best value you have a constant assurance of quality.

When evaluating suppliers, considering value-for-money should guide your comparative picture of their offerings. Even in potholes such as the automotive and electronics industries, they lead horizons in introducing innovations around quality of delivery and competitive price placement. Buyer evaluation for supplier consideration is those who offer highly competitive prices matched by strong product guarantees. The dual benefits expand the procurement process while establishing lifelong relationships that prioritize product integrity.

Innovative pricing and promotional strategies have therefore emerged over time as companies respond to pressures from the economy. Such suppliers would be preferred partners if it were possible to remain flexible in their pricing charges while keeping their services unchanged. So just as consumers are haggling over the best deal across sectors, the same will be seen in aligning supplier selection with holistic standards of value to seal the business in keeping with the eventualities of price movements and marketplace variations.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm