In recent years, the demand for efficient packaging solutions has surged, leading to significant advancements in various industries. Among these innovations, the Liquid Filling Machine has emerged as a pivotal technology, transforming how liquids are packaged and processed. As businesses strive to meet consumer expectations for speed and accuracy, these machines have evolved rapidly, integrating automation, precision engineering, and smart technology to improve production efficiency and reduce waste. This evolution is not merely a response to market demands; it also reflects a broader trend of innovation in manufacturing processes aimed at maximizing productivity.

The increasing complexity of global supply chains and the rise in e-commerce have further fueled the need for reliable and versatile liquid filling solutions. Today’s Liquid Filling Machines come equipped with features that cater to a variety of liquid viscosities and packaging formats, ensuring that manufacturers can adapt to fluctuating market requirements. As we delve into the journey of these machines, we will explore the technological advancements that have shaped their development, the challenges they face in a high-demand market, and the future trends that will likely redefine their role in the packaging industry.

The journey of liquid filling machines has been nothing short of transformative, reflecting advancements in technology and shifts in market demands. Initially, the process of liquid filling was predominantly manual, requiring significant labor input and time. Early machines were simple devices operated by hand, often leading to inconsistent fill levels and inefficiencies. However, as industries began to grow, especially in sectors like food and beverage, pharmaceuticals, and cosmetics, the need for more reliable and efficient filling solutions became crucial.

By the late 20th century, advancements in automation significantly changed the landscape of liquid filling. According to a report by MarketsandMarkets, the global liquid filling machine market reached a value of approximately USD 5 billion in 2020 and is projected to grow at a CAGR of around 6% from 2021 to 2026. This growth has been driven by the increased demand for high-speed production and better quality control, which manual systems simply cannot provide. Automated systems have also incorporated innovations such as servo-controlled technology, enhancing accuracy and speed while minimizing waste.

Today, liquid filling machines are equipped with advanced sensors and software that ensure precise filling, reduced changeover time, and improved user interfaces. Technology such as artificial intelligence and machine learning is being integrated to further optimize operations, predict maintenance needs, and enhance overall productivity. The evolution from manual to automated systems not only showcases technological advancements but also highlights a commitment to meeting the demands of a high-paced market environment. As industries continue to evolve, the role of liquid filling machines will remain pivotal in ensuring operational efficiency and product quality.

| Year | Technology | Features | Market Impact |

|---|---|---|---|

| 1950s | Manual Filling | Simple lever operation, human control | Low efficiency, high labor cost |

| 1970s | Semi-Automatic Filling | Pneumatic systems, operator assistance | Increased production speed, moderate cost |

| 1990s | Fully Automated Filling | Computerized controls, sensors | High efficiency, reduced labor costs |

| 2020s | Smart Filling Technology | IoT integration, predictive maintenance | Optimization of resources, enhanced quality control |

The liquid filling machines market is experiencing a noteworthy evolution, driven by a surge in demand and several key innovations in technology. As the market size is projected to escalate from $6.82 billion in 2025 to $10.39 billion by 2032, at a compound annual growth rate (CAGR) of 6.2%, it is clear that advancements in filling technology play a crucial role in this growth trajectory. These innovations not only enhance efficiency and accuracy but also adapt to the ever-changing requirements of various industries.

One of the significant drivers of this expansion is the incorporation of automation and smart technologies in liquid filling machines. With the integration of AI and machine learning algorithms, manufacturers can now optimize processes, reduce waste, and improve production quality. For instance, innovative features like real-time monitoring and predictive maintenance enhance operational efficiency, allowing companies to respond proactively to potential issues.

Furthermore, the increasing focus on sustainable practices is pushing the liquid filling machine sector to adopt eco-friendly solutions. These advancements include the use of recyclable materials and energy-efficient systems that align with global sustainability goals. As a result, liquid filling technology is not only advancing to meet market demands but also striving to integrate sustainable practices, thereby ensuring a more responsible production environment that appeals to conscious consumers and investors alike.

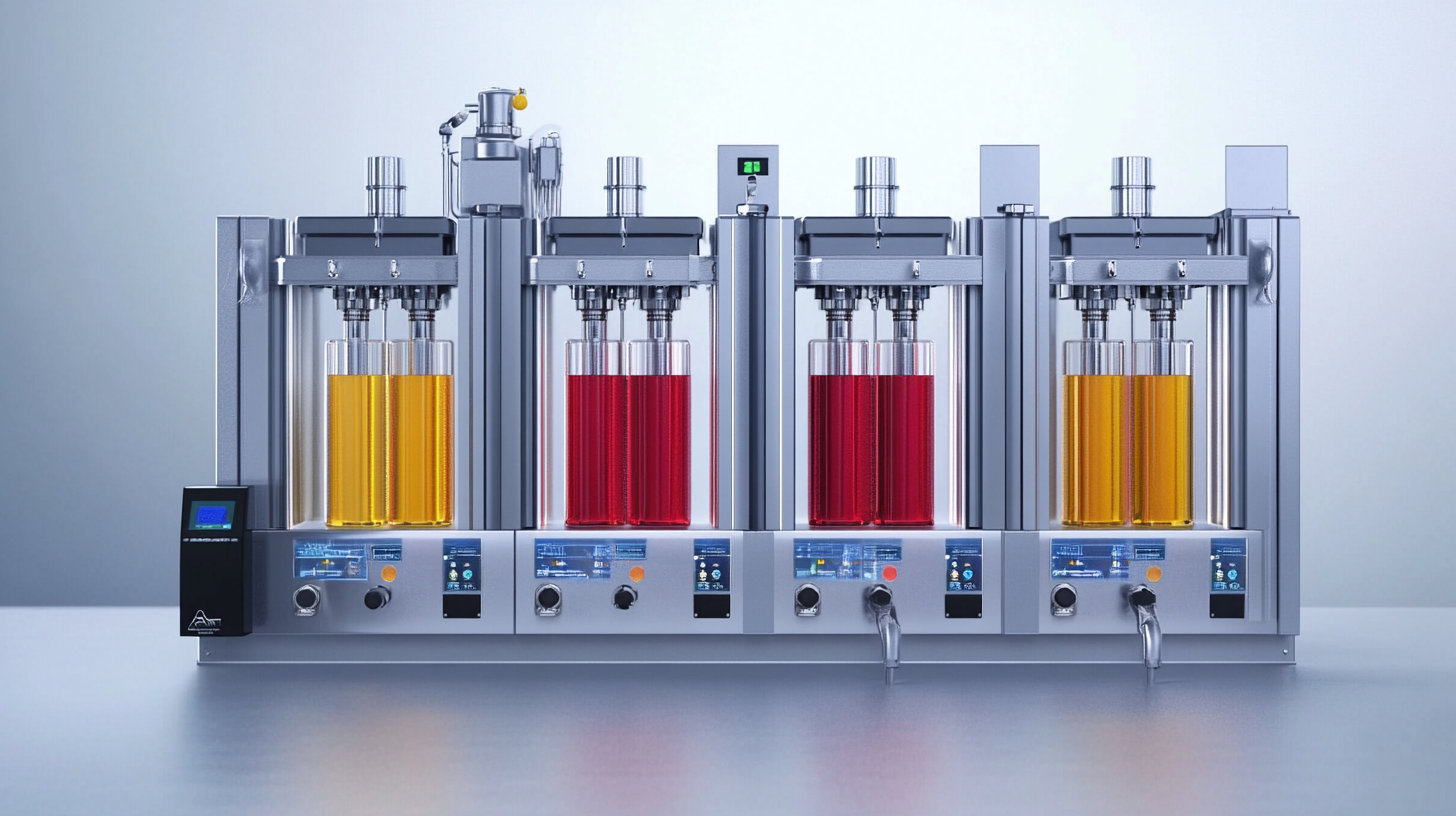

In high-demand industries, the significance of liquid filling machines cannot be overstated. These machines are pivotal in enhancing production efficiency and meeting the growing consumer expectations. As companies strive to optimize their processes, both automatic and semi-automatic liquid filling machines have emerged as essential tools. The automatic machines facilitate rapid filling, which is vital for high-volume production, while semi-automatic options offer flexibility for smaller batches. This versatility allows manufacturers to adapt to fluctuating market demands seamlessly.

The liquid filling machines market is currently experiencing robust growth, with a valuation of approximately USD 8.7 billion in 2023 and an anticipated growth rate exceeding 7.6% through 2032. This surge is driven by increased demands across various sectors including food, pharmaceuticals, and cosmetics. Businesses are increasingly investing in advanced filling technologies to not only enhance productivity but also to ensure precision and reduce waste. As industries continue to evolve, the integration of automation in liquid filling processes stands out as a critical area of focus, promising further innovation and expansion.

Additionally, the market for bottle filling machines specifically highlights a similar trend, wherein the demand for efficient packaging solutions is influencing growth trajectories. The competitive landscape demands that companies innovate continuously to stay ahead. Embracing advanced technologies and automation will be crucial as industries navigate the challenges of a dynamic marketplace and strive to meet the escalating demands for high-quality liquid products.

The liquid filling machine market is currently navigating a complex landscape marked by increasing demand and significant challenges. As chronic diseases rise and populations age, particularly in regions like the USA, the demand for efficient syringe filling machines surges. This trend highlights a pressing need for manufacturers to innovate and adapt their machinery to accommodate higher production rates and improved precision.

Simultaneously, the vertical form-fill-seal (VFFS) machine segment is witnessing robust growth, with projections indicating significant market expansion in the coming years. Manufacturers are faced with the dual challenge of enhancing efficiency while also ensuring that their machinery can handle a variety of liquid products without compromising quality. This necessitates the development of versatile filling solutions that can address diverse customer requirements.

Additionally, the secondary packaging sector presents unique obstacles, particularly in the dairy industry, where packaging integrity and appeal are paramount. As brands strive to differentiate themselves in a competitive market, the integration of innovative packaging solutions becomes crucial. Manufacturers must seek out advanced technologies that not only improve production processes but also meet the evolving demands of consumers and regulatory standards.

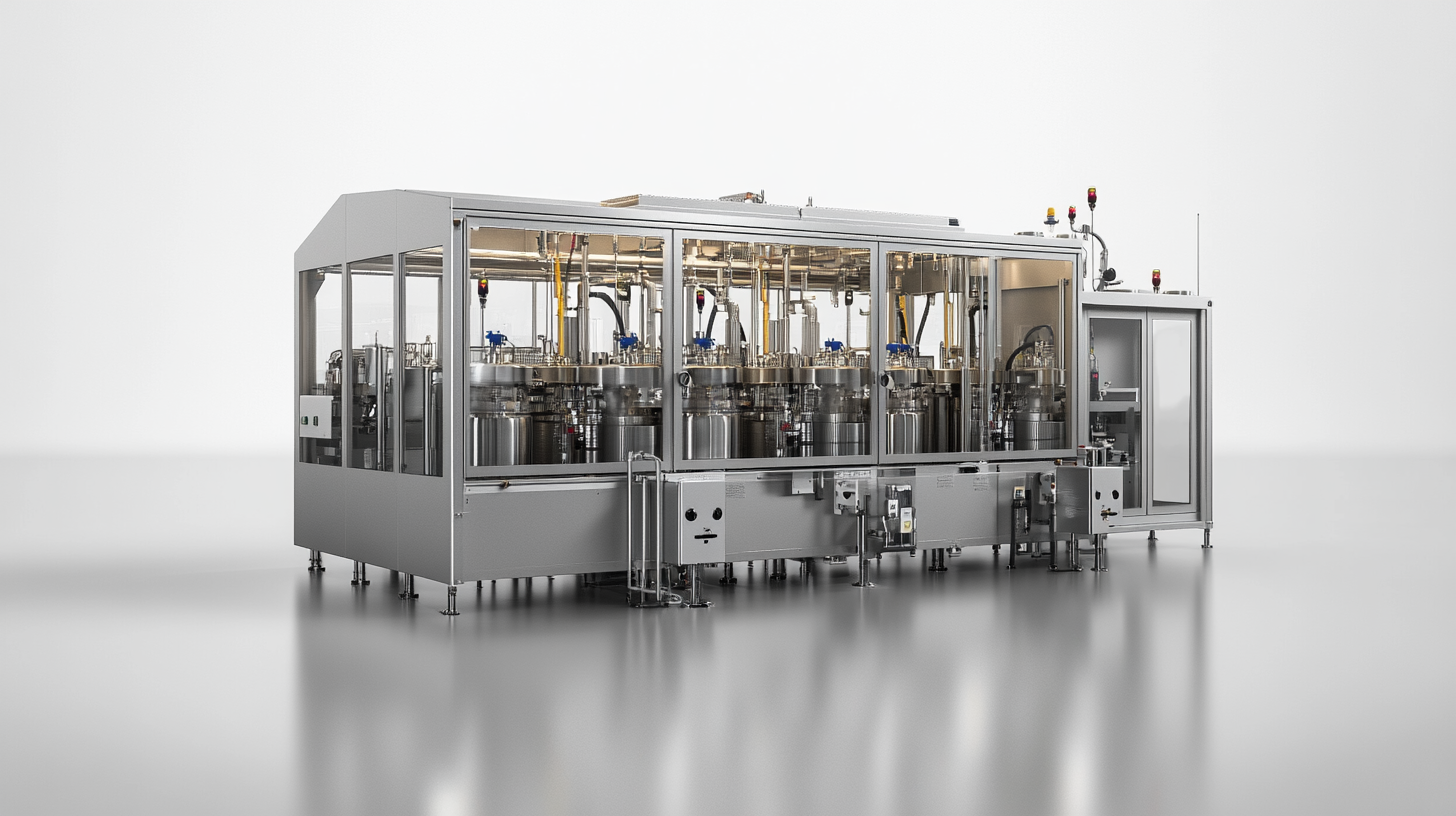

The landscape of liquid filling machines is undergoing a substantial transformation driven by innovations and market demands. As the aseptic filling machine market is projected to reach USD 3.4 billion by 2035, the focus is increasingly on developing machines that can handle a variety of containers, such as vials, syringes, and ampoules. This trend reflects the growing need for precision and versatility in pharmaceutical manufacturing, where regulations are strictly enforced, and the quality of production is paramount. As manufacturers adapt to these requirements, they are investing in robust solutions that streamline the filling process while ensuring compliance with stringent health standards.

In addition to pharmaceuticals, the beverage and food industries are also witnessing significant advancements in liquid filling technologies. The upcoming drinktec 2025 trade show in Munich underscores the urgency for businesses in these sectors to embrace automation and innovative manufacturing strategies. By harnessing advanced technologies, companies can enhance efficiency and minimize waste, aligning with the growing consumer preference for sustainability. The rise of viscous liquid filling machines further exemplifies the industry's responsiveness to diverse product needs, illustrating that as demand shifts, so too do the capabilities of filling equipment.

As we move forward, it is clear that the integration of smart technology and automation will continue to shape the future of liquid filling machines. The impact of digital evolution is already evident in manufacturing processes, and it promises to transform how products are filled, packaged, and delivered. Stakeholders must stay attuned to these trends, embracing innovation to remain competitive in a rapidly evolving market.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm