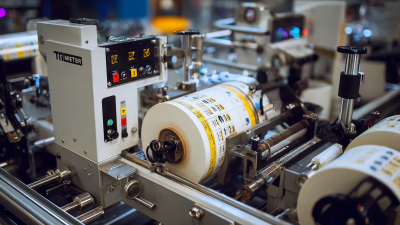

In today's fast-paced manufacturing environment, efficiency is paramount, and businesses are constantly seeking innovative solutions to streamline their processes. One powerful tool that has emerged as a game-changer in the packaging industry is the Label Applicator Machine. This sophisticated piece of equipment not only enhances the speed and accuracy of label application but also significantly reduces labor costs and minimizes waste.

By automating what was once a manual task, companies can improve their overall productivity and ensure that their products meet high standards of quality and compliance. In this article, we will explore the myriad benefits of implementing a Label Applicator Machine in your packaging process, providing insights into how it can help businesses maximize efficiency, boost output, and maintain a competitive edge in the market.

Label applicator machines play a crucial role in modern packaging processes, significantly enhancing efficiency and accuracy. According to a report by Techvision Research, the global labeling machinery market is projected to reach $5.5 billion by 2026, growing at a CAGR of 4.8% from 2021. Such growth underscores the increasing reliance on automated solutions to streamline production lines. These machines not only reduce labor costs but also minimize labeling errors, which can lead to costly product recalls and regulatory issues.

Understanding the basics of label applicator machines reveals why they are essential in various industries, including food and beverage, pharmaceuticals, and consumer goods. There are several types of label applicators, such as semi-automatic and fully automatic models, tailored for different production scales. A study from the Packaging Machinery Manufacturers Institute (PMMI) indicates that 57% of companies report an increase in operational efficiency after integrating label applicator technology into their packaging processes. This technology is vital for maintaining compliance with regulations and enhancing brand visibility through consistent labeling, ultimately driving consumer trust and sales growth.

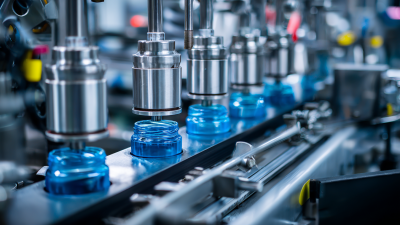

In today's fast-paced packaging industry, implementing label applicator technology offers several key benefits that can significantly enhance operational efficiency. According to a recent industry report by Smithers Pira, automation in packaging processes can lead to a productivity increase of up to 30%. By utilizing label applicator machines, businesses can streamline their packaging lines, reducing the time spent on manual labeling and minimizing human error. This not only boosts output but also ensures consistent label placement, thereby enhancing brand presentation.

Moreover, the reduction in labor costs and material waste are noteworthy advantages of adopting label applicator technology. A survey by PMMI found that companies that integrated automated labeling systems experienced a 20% decrease in labor expenses and a 15% reduction in label waste. This translates into substantial cost savings that can be reinvested into other areas of the business. As companies strive for sustainability, the efficiency gained from label applicators aligns perfectly with environmentally-friendly practices, as it reduces excess materials and improves overall operational sustainability.

When selecting the right label applicator machine for your business, it is crucial to assess your specific packaging needs. Begin by evaluating the types of products you need to label. Consider factors such as the size, shape, and material of your products, as these will determine the type of applicator you require. Some machines are designed for flat surfaces, while others can handle irregular-shaped items. Understanding these requirements will help narrow down your options significantly.

Next, think about the production speed and volume you need to achieve. Different label applicators come with varying throughput capabilities, so it's essential to align the machine's performance with your operational expectations. Additionally, consider the ease of setup and maintenance. A user-friendly machine that minimizes downtime will contribute to overall efficiency. Finally, look for additional features such as automation capabilities, sensor technology, and integration options with existing packaging systems, which can further enhance your labeling process. By carefully considering these factors, you can choose a label applicator that not only meets your current needs but also supports your business's growth.

To optimize your packaging process with label applicators, implementing best practices is crucial. First, ensure that your label applicator is correctly calibrated to match your production speed and product dimensions. Calibration not only improves the accuracy of label placement but also minimizes waste. Regularly scheduled maintenance and inspections can prevent downtime and maintain machine performance, ensuring a smooth workflow.

Additionally, consider integrating the label applicator with your existing packaging line. This integration can streamline operations and enhance productivity. Utilizing automated systems for labeling and packing reduces manual input, which often leads to human error. Training employees on the proper use of label applicators and providing them with a thorough understanding of the equipment significantly increases efficiency. The combination of technology and skilled personnel plays a critical role in maximizing the benefits of label applicators in your packaging process.

Maintaining your label applicator machine is crucial for ensuring its longevity and optimal performance. Regular maintenance practices, such as cleaning the applicator and inspecting its components, can prevent malfunctions that may disrupt your packaging process. Dust and debris can accumulate in various parts of the machine, leading to inefficiencies or even damage over time. Establishing a routine maintenance schedule allows you to detect issues early and ensures that the machine operates smoothly.

Another key aspect of maintenance is monitoring wear and tear on the applicator's moving parts and label dispensing mechanisms. Components such as rollers or sensors may require lubrication or replacement to maintain their functionality. Investing in quality replacement parts and following manufacturer guidelines not only extends the life of your machine but also guarantees consistent labeling quality. By prioritizing these maintenance activities, businesses can maximize the effectiveness of their label applicator machines, ultimately enhancing productivity in the packaging process.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm