In an era where efficiency and precision are paramount, the role of labeling machines in modern industries is undergoing a transformative revolution. As businesses strive to enhance productivity and streamline operations, the global labeling machine market is projected to grow significantly, with a reported CAGR of around 5.6% from 2021 to 2028 (Source: Market Research Report). This surge is driven by the increasing demand for accurate labeling in sectors such as food and beverage, pharmaceuticals, and e-commerce, which collectively value the necessity of compliance and branding.

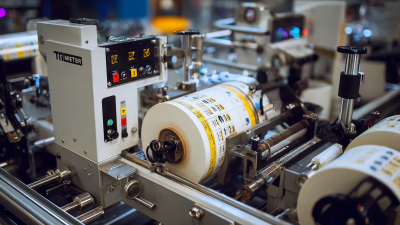

With advancements in technology, such as automation and integration with smart systems, labeling machines are evolving from simple applicators to sophisticated devices that enhance operational efficiency and reduce waste. As we delve into the future of labeling machines, it becomes evident that their evolution is not just a trend but a necessary adaptation to evolving manufacturing and consumer demands.

The landscape of packaging is rapidly evolving, particularly in the realm of labeling machines, where emerging technologies are driving significant advancements in efficiency. According to a recent report by Smithers Pira, the global labeling market is expected to reach $50 billion by 2025, with a substantial shift towards automation and digitalization. This trend is largely fueled by innovations such as smart labeling, which utilizes RFID and QR code technologies to enhance tracking and inventory management processes, effectively reducing labor costs and increasing production speed.

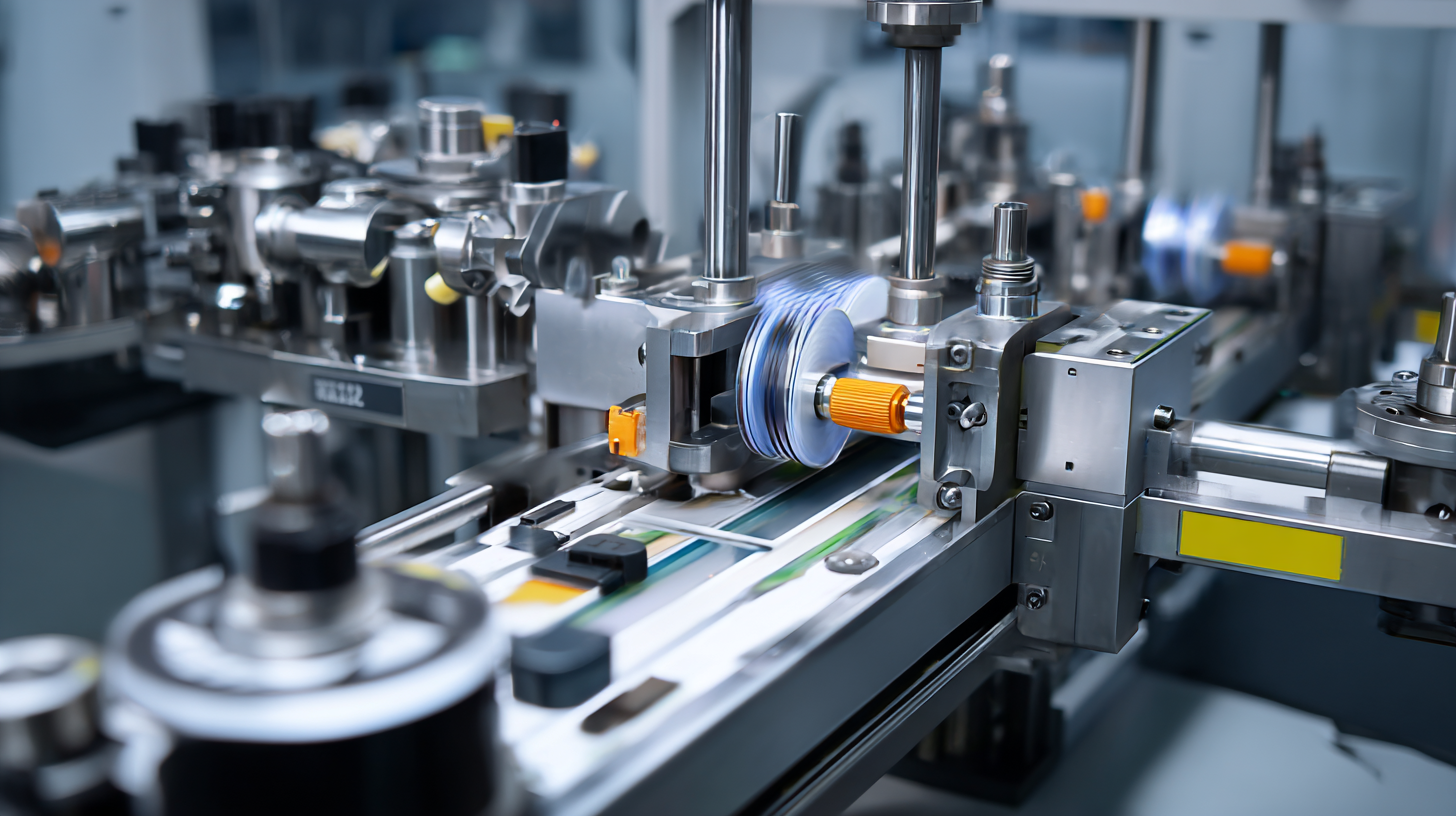

Moreover, the integration of AI and machine learning in labeling machines is setting new benchmarks for operational efficiency. These intelligent systems can analyze production lines in real-time, adjust labeling speeds, and maintain quality control with minimal human intervention. A study by MarketsandMarkets indicates that the market for automated labeling machines is projected to grow at a CAGR of 7.9%, reaching $5.9 billion by 2026. This growth underscores the growing importance of adaptability and precision in modern manufacturing settings, showcasing how these technological advancements are not just enhancing efficiency, but also redefining industry standards.

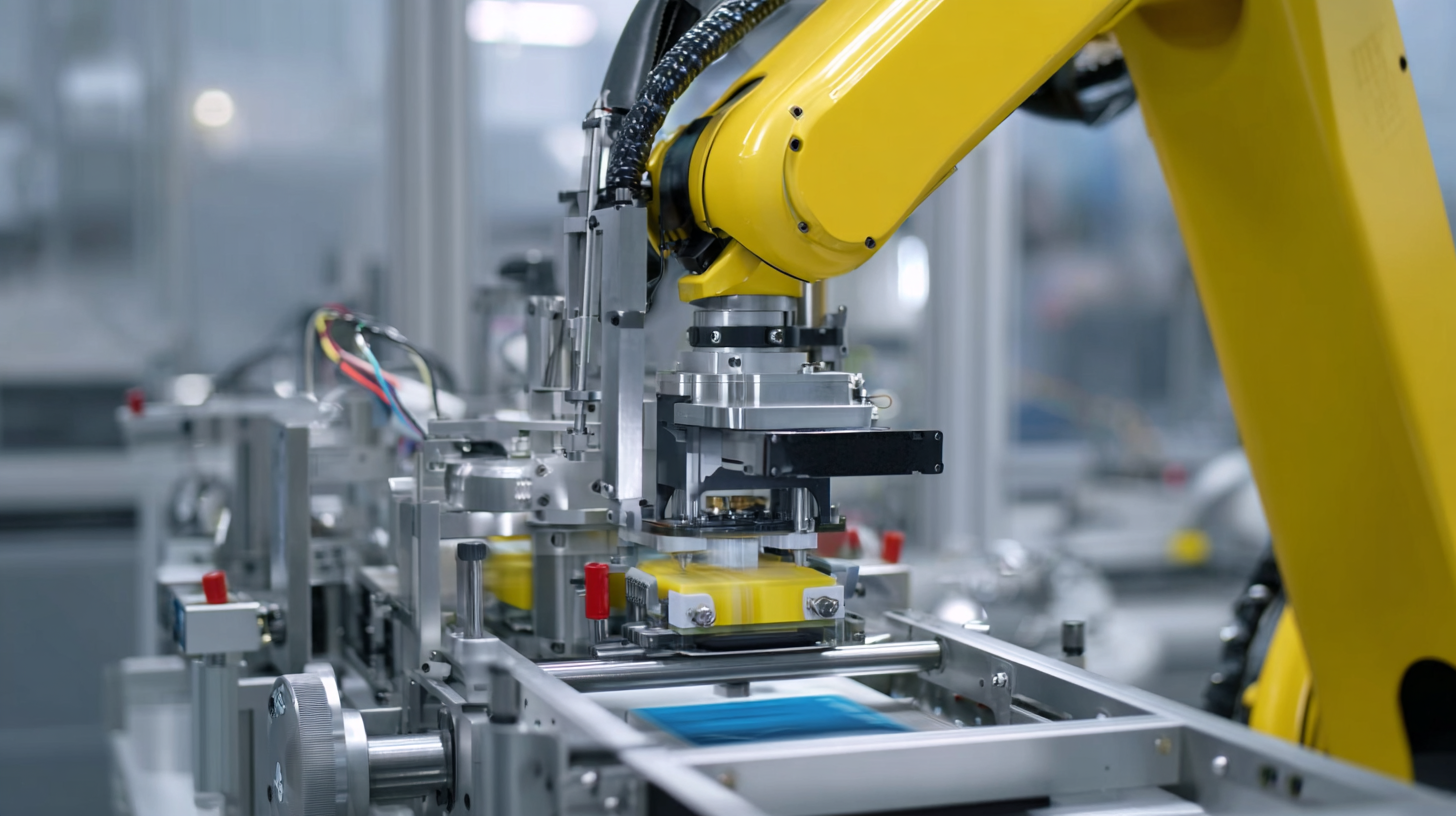

The advent of automated labeling machines has significantly transformed the packaging landscape in various industries, leading to remarkable enhancements in production speed. By employing advanced technologies such as sensors and robotics, these machines optimize labeling precision and efficiency, allowing businesses to meet increasing demands without compromising quality. This automation minimizes human error, reducing the time taken for each labeling cycle, which ultimately accelerates overall production timelines. The ability to rapidly adjust labeling formats for different products also permits manufacturers to swiftly adapt to market changes.

In addition to increased speed, automated labeling systems contribute to substantial cost reductions. By streamlining processes and reducing labor costs associated with manual labeling, companies can allocate resources more effectively. Moreover, the inherent accuracy of automated systems leads to decreased material waste, further boosting profitability. These cost benefits, coupled with enhanced operational efficiency, empower industries to not only maintain competitiveness but also strategize for scalable growth in an ever-evolving market.

In the contemporary landscape of manufacturing, the shift towards sustainable packaging solutions is becoming increasingly important. Eco-friendly materials, such as biodegradable plastics and recycled paper, are at the forefront of this movement. These materials not only reduce environmental impact but also cater to the growing consumer demand for sustainable products. Companies are innovating by incorporating these materials into their packaging processes, ensuring that the entire lifecycle of a product is environmentally responsible.

Labeling techniques have also evolved, aligning with the emphasis on sustainability. Digital printing technology enables companies to produce labels using water-based inks and eco-friendly adhesives, minimizing waste and harmful emissions. Additionally, smart labeling solutions, like QR codes, allow consumers to access information about the packaging’s recyclability and the product’s environmental footprint. This not only enhances transparency but also encourages consumers to make informed choices, fostering a culture of sustainability in the marketplace. As industries continue to prioritize eco-friendly practices, the integration of sustainable materials and innovative labeling techniques will play a crucial role in revolutionizing packaging efficiency.

In modern industries, data-driven decision-making has emerged as a critical approach for enhancing operational efficiency, particularly in the realm of labeling processes. By leveraging advanced analytics, companies can analyze vast amounts of data generated during packaging operations to unveil insights that were previously inaccessible. This analytical approach allows businesses to identify bottlenecks, optimize workflows, and streamline their labeling practices, ultimately resulting in increased productivity and reduced costs.

The integration of data analytics into labeling machines transforms how companies manage their operations. Real-time data monitoring enables businesses to track performance metrics and detect anomalies promptly, facilitating proactive adjustments to maintain optimal functionality. Predictive analytics also play a significant role, as they provide forecasts that guide inventory levels and production schedules. As industries continue to embrace this technological evolution, the potential for improved labeling efficiency grows, paving the way for a more agile and responsive manufacturing environment.

The integration of AI and IoT technologies is poised to transform the operations of labeling machines in modern industries. As companies strive for enhanced efficiency and accuracy, the use of intelligent labeling systems will become paramount. According to industry reports, the labeling machines market is projected to grow significantly, with a compound annual growth rate (CAGR) of over 5% reaching approximately $5 billion by 2025. This growth is driven by the increasing demand for automation, which not only streamlines production processes but also ensures compliance with emerging industry standards.

Tips: Embrace the integration of IoT sensors in labeling machines for real-time data analytics and improved traceability. This can lead to better inventory management and reduced operational downtime.

Additionally, the adoption of AI in labeling machines allows for advanced features such as image recognition and predictive maintenance, which help optimize performance and minimize errors. As reported, industries implementing these technologies have seen productivity improvements of 20% or more. Staying ahead in this rapidly evolving landscape will require businesses to invest in next-generation labeling solutions that harness the power of AI and IoT.

Tips: Regularly update software and algorithms used in labeling systems to ensure they adapt to new industry standards and customer needs, maximizing both efficiency and compliance.

| Feature | Description | Impact on Industry | Future Adoption Rate (%) |

|---|---|---|---|

| AI Integration | Use of artificial intelligence for predictive maintenance and quality control. | Enhances operational efficiency and reduces downtime. | 75% |

| IoT Connectivity | Devices connected to the internet to collect and analyze data in real-time. | Improves supply chain transparency and inventory tracking. | 80% |

| Sustainability Features | Use of eco-friendly materials and processes in labeling. | Meets increasing consumer demand for sustainable practices. | 65% |

| Automation | Fully automated labeling processes to reduce manual labor. | Increases speed and accuracy of labeling operations. | 85% |

| Smart Labeling | Labels with QR codes and NFC technology for enhanced consumer interaction. | Enhances customer engagement and provides real-time information. | 70% |

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm