Shrink Tunnel technology is essential for packaging efficiency in various industries. This system applies heat to shrink film around products, ensuring secure wrapping. Properly utilizing a Shrink Tunnel can enhance productivity and reduce waste. However, many companies overlook key aspects of this process.

Temperature settings and conveyor speed significantly influence the results. A poorly calibrated Shrink Tunnel can lead to under-shrinking or over-shrinking. Both issues can cost time and resources. Operators must stay vigilant and adjust parameters according to the film type and product dimensions.

The design of the Shrink Tunnel itself also plays a crucial role. Insufficient airflow can result in uneven shrinking. Regular maintenance checks can prevent these problems. Constant learning and adjustments are vital for optimal performance. Hence, a commitment to ongoing refinement is necessary for achieving the best results.

Shrink tunnels play a vital role in modern packaging systems. They efficiently shrink wrap products using heat. This process can improve the appearance of packaged items. However, achieving optimal results requires careful attention. Many users overlook temperature settings. An improper heat level can lead to issues like uneven shrinkage or damage to the products.

When using a shrink tunnel, the speed is crucial. If the conveyor moves too fast, products might not shrink properly. Conversely, a slow speed could lead to over-shrinking. It's essential to find a balance for each type of product. Additionally, the positioning of the items in the tunnel matters. Misaligned packages may not receive uniform heat, affecting the overall finish.

Another common oversight is maintenance. Regularly cleaning and checking equipment ensures consistent performance. Failing to do so can result in breakdowns or inferior packaging. Operators should also monitor the quality of film used. Thin or low-grade materials may not hold up during shipping. These reflections highlight that, while shrink tunnels enhance packaging, they require mindful management to achieve their best.

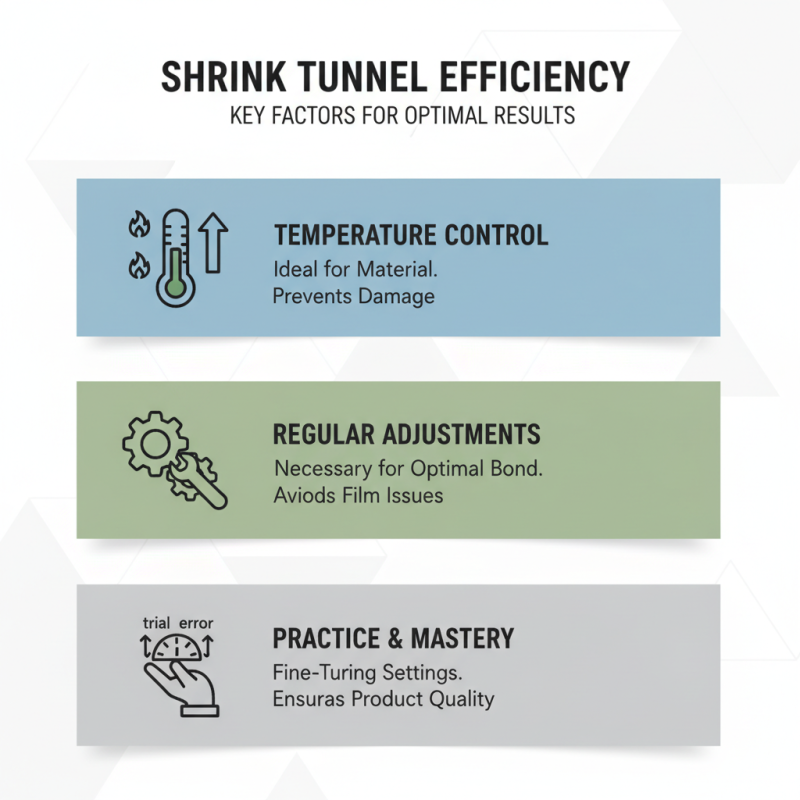

When considering shrink tunnel efficiency, several key factors come into play. The temperature is crucial; it must be ideal for the material being used. Too low, and the film won't bond properly. Too high, and you risk damaging the product within. It takes practice to master these settings. Regular adjustments can be a hassle but are often necessary for optimal results.

Airflow also significantly impacts shrink tunnels. Poor airflow can cause uneven shrinkage, leading to less than perfect packaging. Operators should check the fan settings often. Filters may become clogged, which affects performance. A clear path for air is essential, and cleaning routines should be consistent.

Finally, the speed of the conveyor belt plays a vital role in the shrink process. If the belt moves too quickly, the film may not shrink evenly. Conversely, a slow speed might waste energy and time. Operators can experiment with different settings to find the right balance. It’s important to document these adjustments for future reference. Reflecting on past experiences can help fine-tune operations and improve efficiency.

Setting up a shrink tunnel requires attention to detail. Begin by ensuring the shrink tunnel is positioned to allow smooth entry and exit of products. The temperature settings must be precise; too high can damage packaging, and too low will cause insufficient shrinking. Regularly check the tunnel's efficiency. A poorly functioning tunnel can lead to wasted materials and time.

Consider the conveyor speed. It should match the packaging line's flow. If the speed is too fast, the products may not shrink properly. If it's too slow, you risk delays. Evaluate the positioning of the shrink film. Wrinkles or overlaps can ruin the presentation of the final package. A neat finish is crucial.

Don't overlook routine maintenance. Without it, the shrink tunnel might underperform. Inspect components regularly for wear and tear. Document any issues that arise during operation. Reflection on these experiences helps refine the process. Continuous improvement is key to achieving optimal packaging efficiency.

Shrink packaging offers efficiency but comes with challenges. One common issue is uneven heat distribution. This can cause inconsistencies in shrinkage. Products may come out tightly wrapped in some areas and loose in others. This unevenness can lead to product damage or presentation flaws.

Another challenge is the choice of shrink film. Not every film works for every product. Some films may not adhere properly or may impact visual appeal. Testing different films is essential to identify the right fit for each product. It’s important to understand the material characteristics like thickness and sealing properties. Finding the perfect balance takes time and experimentation.

Moreover, maintaining equipment is crucial. Regular maintenance can prevent breakdowns and ensure smooth operation. Often, shrink tunnels are neglected until a problem arises. This oversight can lead to costly production downtime. It’s a balance between efficiency and proactive management. Continuous evaluation and adjustment of techniques will lead to better results over time.

Maintaining and upgrading shrink tunnel equipment can significantly enhance packaging efficiency. Regular maintenance checks prevent unexpected breakdowns. These checks include cleaning heating elements and inspecting seal mechanisms.

Neglecting such simple tasks can lead to inefficiencies and increased downtime.

Upgrading equipment can be a game-changer. Investing in modern technology improves performance and speed. Newer models often include features that enhance energy efficiency. However, budget constraints or lack of knowledge might deter companies from pursuing upgrades. It's crucial to assess actual needs versus perceived benefits.

Moreover, not all upgrades yield immediate results. It might take time to train staff on new systems. Resistance to change is common, posing additional challenges. Balancing new technologies with existing processes requires careful planning and patience. Ignoring these aspects could hinder overall productivity.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm